What is a Boiler?

The boiler in industries is equipment that converts water into steam economically and efficiently. This steam is used for the generation of power for textile processing and Also for conditioning, the weaving shed.

The first boiler was also invited with a safety valve in years back 1679 by Denis Papin of France. He invented the pressure cooker and basically suggested the design of the first cylinder and piston steam engine. After that boilers is made and used in England by the start of the 18Th century. Earlier Boilers are made with Wrought iron after when the advantage of high pressure and temperature was realized the manufacturing turned to steel. Stephen Wilcox worked with George Babcock to invent the first water tube steam boiler. Also, this boiler allowed safer and more efficient production of steam

The energy liberated by the combustion of fuel is used to increase the enthalpy of fluid passing through the boilers. So some of the energy liberated tends to leave with flow gases through the chimney. Also, an attempt is made to regain this energy to the maximum possible extent by installing an economiser and air pre-heater. So this steam generated by boilers is used for steam engines, and steam turbines in power plants, and steam is also used in the process industry. These boilers are classified as

For economic purposes, all boilers consist of a multi-tubular system

- Horizontal multi-tubular system

- vertical multi-tubular system

Boilers are of two types

- Fire tube boiler

- water tube boiler

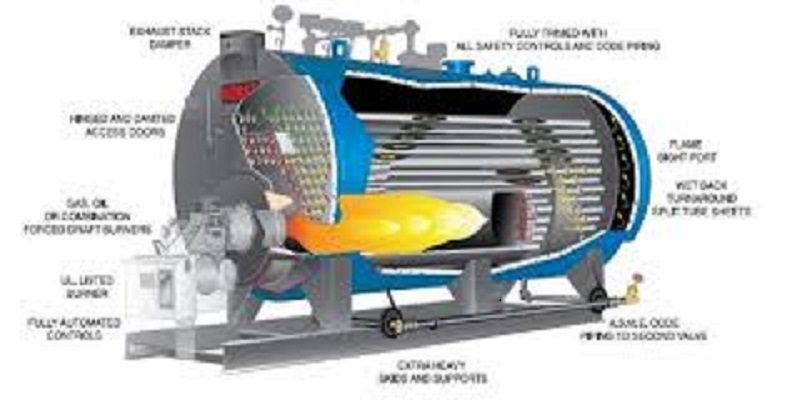

α. Fire tube boilers

In fire tube boilers fuel is inside the tubes and so water is outside the tubes. Also, these boilers have medium capacity and low-pressure

up to 200 PSI. Also, they do not give a constant supply of heat and produce 10,000 lbs/hour of steam only. They consume less fuel and are economical in both fuel and space but are not efficient.

β. Water tube boilers

In the water tube boiler water is inside the tubes and so outside is fuel. Basically, they are used in big industries. Also, they are of high pressure up to 500 PSI and produce 100,000 lbs/hour of steam. They require much more space and fuel than fire tube boilers.

What is the Capacity of boilers?

The capacity of boilers is indicated by the maximum amount of steam generated in Kg/hour or ponds/ hour on a particular pressure.

Selection of steam boilers

The following factors can be considered before selecting steam boilers

- The quantity of steam required at what pressure

- Floor area available

- Initial cost, operating cost also, and maintenance cost.

- Probable load factor

- Types of fuels

- Also, Water is available

What are the properties of a good boiler?

A good boiler should have the following qualities,

- It should be reliable and also should work satisfactorily under variable load work.

- The tubes should not be choked and also will be strong enough to meet the corrosion.

- It should be equipped with safety devices and accessories.

- It should be economical from a fuel consumption point of view, with low initial cost and also low operational maintenance cost.

- It should be easy to maintain, repair and also inspection

Compersion between fire tube and water tube boilers

below the chart, we can understand the difference as

| Water Tube Boilers | Fire Tube boilers |

| Quicker evaporation | slow evaporation due to a large amount of water being heated |

| Water circulates inside the tube and fire and furnace gases are outside the tube | Hot gases from the furnace are circulating inside the tube while water surrounded outside |

| It generates steam at high pressure of up to 500 PSI | It generates steam at a low-pressure maximum of up to 200 PSI |

| Also, It produces steam up to 100,000 pounds per hour | This type of boiler can produce steam up to 10,000 ponds/ hours |

| It has more efficiency of up to 90% | this type of boiler has a maximum efficiency of 75% |

| Its operating cost is high | Its operating cost is low |

| water tube boiler has low storage of steam | fire tube boiler has high storage as compared to water tube boiler |

| This type of boiler is suitable for bigger industries (like power plants) | fire tube boilers are used in low-scale to medium-type industries (textile industries) |

| The bursting chances of this type are more | It has low bursting chances |

| water treatment is necessary, since the small deposit in the tube may cause overheating resulting in the bursting | water treatment is not necessary |

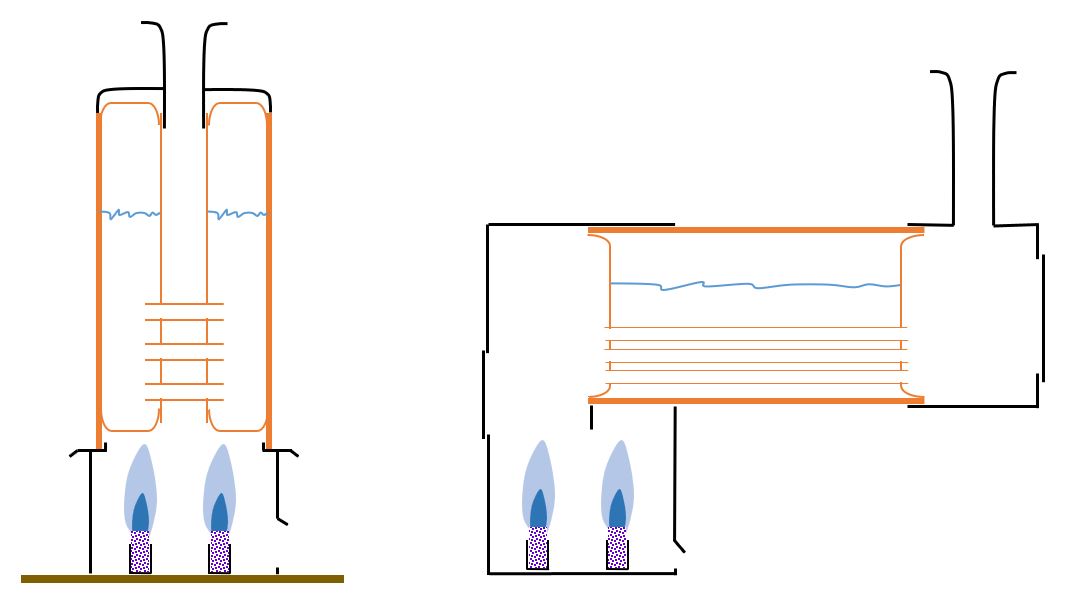

i. Horizontal tube boilers

They are low-pressure and medium-pressure boilers. Also, their storage capacity is excellent. So, in the textile industry, medium-type boilers are used

ii. Verticle tube boilers

They are of high capacity and pressure and are used in heavy industry.

What is a Lancashire tube boiler?

For both horizontal and vertical tube boilers advantages, hence boilers are also converted into inclined types. Horizontal type and fire tube boilers were first invented in 1844, by William Fairbairn. So, In textile industries, a special type of boiler called Lancashire boilers

It has a capacity of 50,000 lbs/hour

These have a pressure of 100~200 PSI.

Also, these are economic fuel boilers

Impurities in boiler feed water

Water is a universal solvent so pure water is rarely found. Additionally, a boiler in industries should need purification to some extent.

Inorganic impurities

Suspended (clay, salt, sand, oil, and metal oxides, dissolved (HCO3, CO3, SO4, Cl, NO3 of Ca, Mg, Na, K, Fe, etc)

Organic impurities

Suspended ( vegetable, animal matter, bacteria, and also industrial and sewage waste), dissolved ( certain organic acids)

Dissolved gases

O2, N2, CO2, SO2, CH4, H2S, etc.

Microorganism

In suspended form bacteria, algae, fungus, etc.