The mechanical properties of metal determine how its use of the metal and develop a standard that can be expected. and also show response to an external load Which includes how they behave (twist, elongate, compress) or break as a function of applied, load, temperature, time, and other conditions. Mechanical properties are termed by stress and strain, elastic deformation, and plastic deformation.

what are the mechanical properties of the material?

In textile industries, its importance is multiplied, detailed explanation as under

What is toughness?

Toughness is the amount of energy that material can absorb

What is load?

The external force applied on the body per unit area is called the load

Hence, load=F/A=N/m2

What is stress?

Stress is an internal force of a body against the externally applied force.

When some external forces or loads getting act upon a body then internal forces are set up at various sections of the body. Which resists the external force, this external force per unit area on any section of a body is known as stress

F=Stress

P= force of the load

A= area of cross

The unit of stress in the MKS system(meter-kilogram-second) is Kg/cm2 or in the CGS system(centimetre gram second system) is N/mm, N/m2

What is the MKS system?

The mks system is called the metric system as meter, kilogram, and the second are the fundamental units. The mks system of unit measurement is based on the metric system. Also, Pascal is a unit of pressure in the mks system equivalent to one newton per square meter.

What is the CGS system?

The CGS system is called the coherent system unit as centimeter for distance, gram for mass, and second for time. The CGS system is based on the fundamental unit of the system

What is a strain?

When a system of forces or loads acts upon a body it undergoes some deformation.

Deformation per unit length is known as unit strain or strain,i.e

e=Δl/L

Δl= change in length

L=original length

A different form of stress

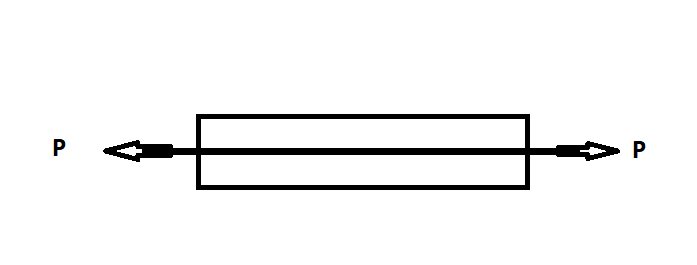

What is tensile stress?

When a body is subjected to two equal and opposite axial pulls, then stress induced at any section of a is known as tensile stress.

Hence, tensile stress=ft=p/A

Where p=axial load

A=cross-sectional area

Due to tensile load, there will be an increase in the length of the body.

What is a tensile strain?

The ratio of increase in length to original length is known as tensile strain.

et=Δl/L

Where Δl=change in length

L=original length

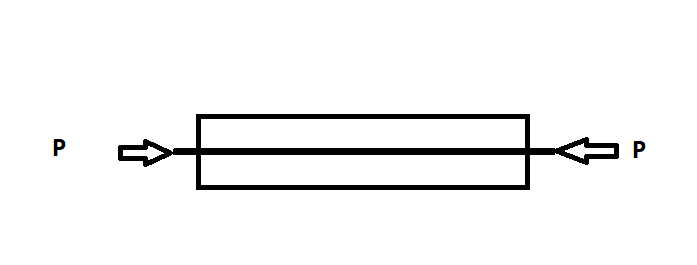

What is compressive stress?

When a body is subjected to two equal and opposite axial pushes p then the stress induced at any section of a body is known as compressive stress

fc=P/A

Where P=axial load

A= cross-sectional area

fc=compressive stress

Due to compressive stress, there will be a decrease in the length of the body.

Compressive strain

The ratio of the decrease in length to the original length is called compressive strain i.e.

Ec=l/L

What is shearing stress?

When a body is subjected to two equal and opposite forces acting tangentially across the resisting section then the body tends to shear off the section, the stress-induced is called shearing stress. Also, the corresponding strain is known as the shear strain

Fs=tangential force/resisting force=P/A

Consider a body consisting of two plates connected by a rivet. In this increases the tangent force tends to shear off the rivet, so the shear stress, in this case, can be given by

fs=P/A=P/(πd2/4)=4P/πd2

Where P=load

d=diameter of the rivet

A=cross-sectional area of rivet

Metal mechanical properties

The mechanical properties of the metal are those which are associated with the ability of the material to resist the mechanical forces and also loads

What is the strength?

It is the ability of the material to resist externally applied forces, hence, known as strength.

What is stiffness?

It is the ability of a material to resist deformation under stress (also with breakdowns), which is known as stiffness.

What is elasticity?

It is a property of a material to regain its original shape after deformation. When external forces are removed, which is known as elasticity.

What is plasticity?

It is the property of a material that retains the deformation under load permanently, which is called plasticity.

What is ductility?

It is the property of metal enabling it to draw into wires with the application of tensile force is called ductility. Ducted material must be both strong and elastic. Hence, mild steel, copper, aluminum, etc. are ducted materials.

What is brittleness?

It is the property of material opposite to ductility, which is called the brittleness of the material. So it is the property of breaking material with a little permanent deformation. Brittle material when subjected to tensile loads is broken without any visible elongation. Also, cast iron is a brittle material.

What is malleability?

Malleability is a special case of ductility that permits material to be rolled or hammered into thin sheets. Also, a malleable material should be strong. So the malleable material commonly used in engineering material practice is lead, soft steel, and aluminum.

What is elongation?

When a material is pulled in a testing machine for the purpose of loading its tensile strength, stretch takes place before the bar of fractures. So the elongation is the amount of the stretch. It is generally expressed as the percentage(%) of its original length.

What is hardness?

The hardness of the metal is its ability to withstand. The machinability and ability to cut are also due to hardness.

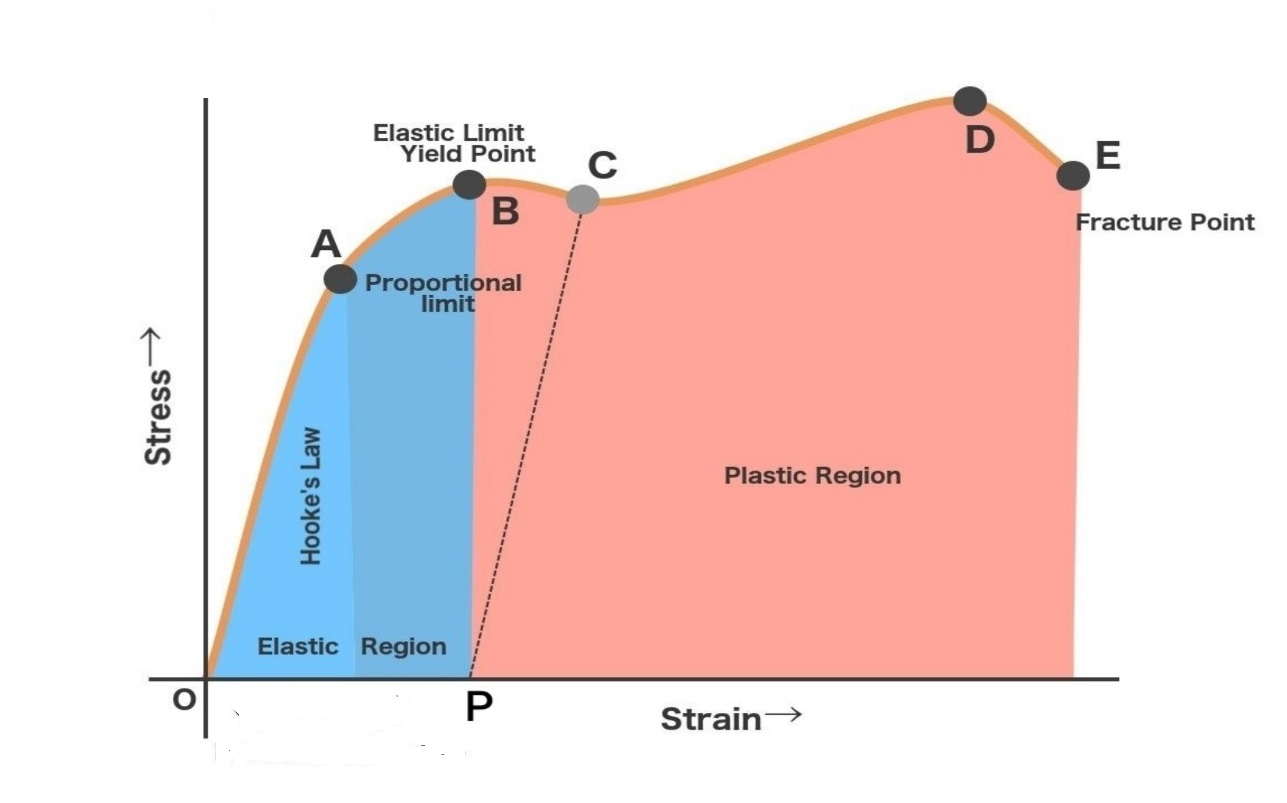

What is the stress-strain curve?

0→A(proportional limit)

A→B(elastic region)

B→C (Plastic region)

C→D are yielding points (giving up resistance)

C = upper yielding point

D= lower yielding point

Proportional limit

From point, O to A is a straight line which represents that stress is proportional to strain. Beyond point (A), the curve deviates from the right line. Hence, hooks law acts up to (A) and is known as the proportional limit.

Elastic limit

The important mechanical properties of the metal are described as the elastic limit of the load is increased beyond point A up to B. The material regains its shape and size when the load is removed. Also, this means that the material has an elastic proportion.

Yield point

The yield point of the material is stressed beyond a point (B). The plastic stage will reach i.e. on the removal of load, so the material will not be able to recover its original size and shape.

Beyond point (B) the increases at a faster rate with any increase in stress until point (C) is reached, at this point material yields before the load, an appreciable increase in strain without an increase in stress. In mild steed small load drops to defter yield so there are two yield points upper and lower.

Ultimate stress

At point (D) the specimen regains some strength and a higher value of stresses are required for higher strain than those at (A) and (D). The stress goes on increasing till point (E) is reached. Also, with the gradual increase in stress followed by a uniform reduction of its cross-sectional area at (E), the specimen attains the maximum stress known as ultimate stress.

Working stress

In the design to keep the stress lower than the maximum or ultimate stress, this stress is known as working stress.

The factor of safety (F.O.S)

It is the ratio of maximum stress to working stress.

i.e. F.O .S max stress/work stress