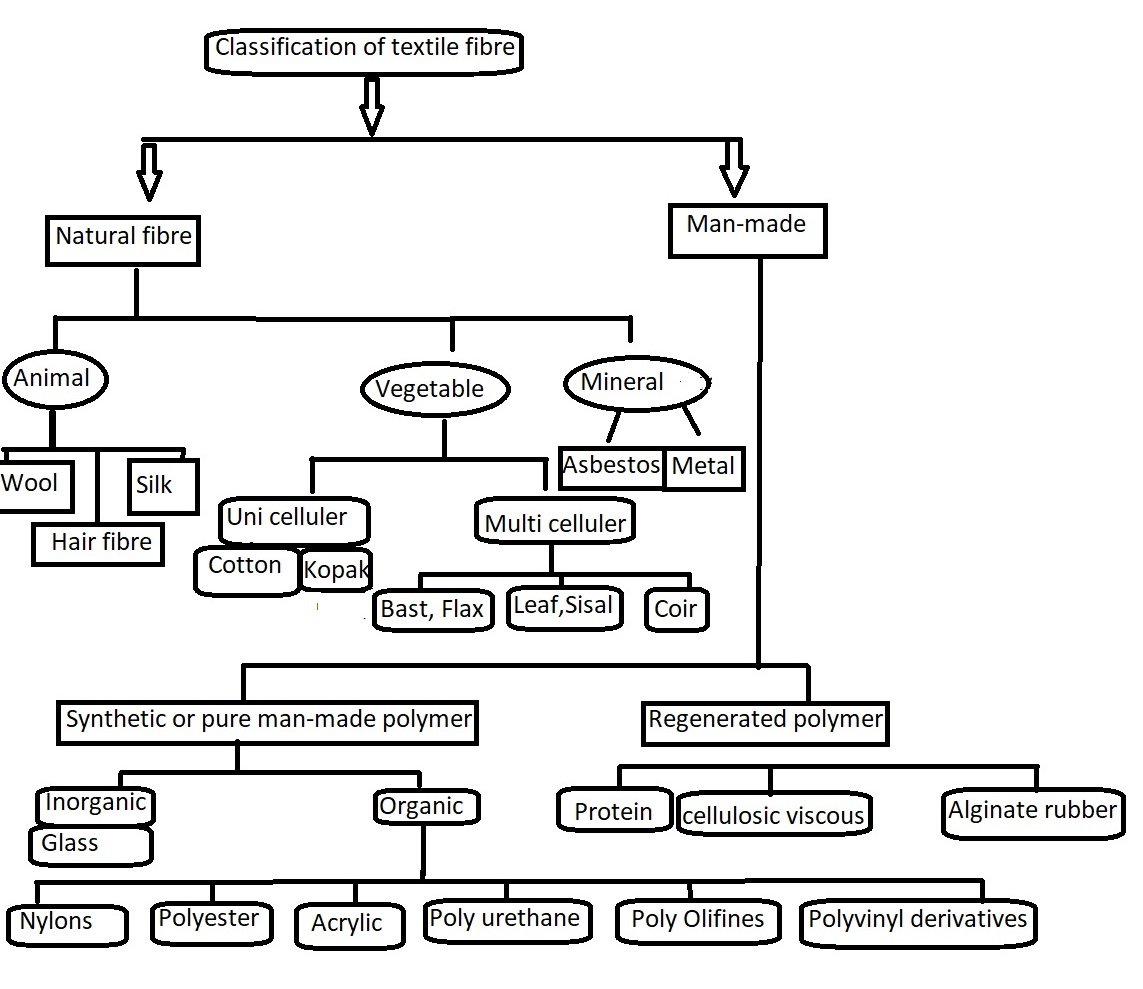

Classification of textile fibres into two main categories, the natural and man-made fibre in the classification of textile fibre.

Classification of textile fibres chart

Vegetable fibres

- Bast fibre (jute,ramie, flax, hemp)

- Leaf fibres (sisal, abaca)

- Seed fibres (cotton, bombax, kapok, coir)

Animal fibres

- Silk

- Wool and hair fibres

Mineral fibres

- Asbestos fibre

- Silver, gold, copper etc.

Synthetic or pure man-made fibres

- Nylons

- Polyesters

- Acrylic fibres

- poly urethanes

- Poly olefines

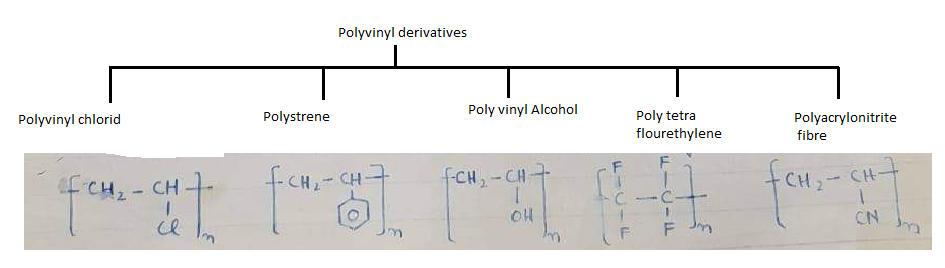

- Polyvinyl derivatives

Regenerated fibres

- Casein fibres

- Viscose rayon

- Acetate Rayon

- Cuprammonium rayon

- Alginate fibres

- Cellulose triacetate

Physical properties of fibres

Fibre

It is the smallest unit of textile products. Also, Fibres are used to make yarn. So the important properties (general terms) are

Length of fibre

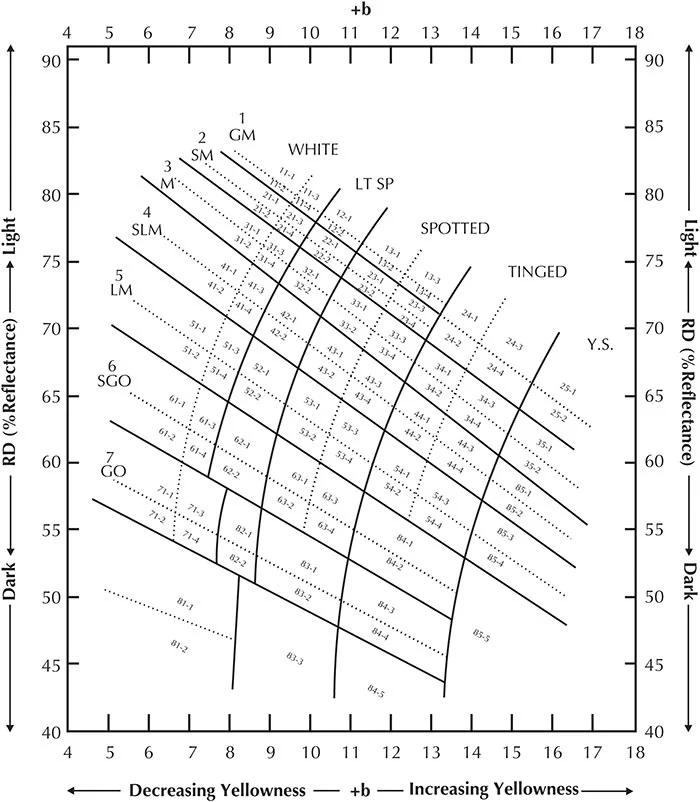

The staple length term is used for the length of fibres. It is denoted by S.L. It is measured in inches. Also, the staple length is measured with the help of a fibro-graph in cotton fibre.

Fineness of fibre

The weight of fibres expressed in ug/inch is known as the fineness of fibre or conversely, the weight of one inch of fibre in microgram (ug).

1 u = 10-6

If 2→2.5 ug/inch Ideal fibre

2.5→3.5 ug/inch fine

3.5→4.5 ug/inch average

4.5→5.5 ug/inch rough

Strength of fibre

There are two terms used for the strength of a fibre

- Tensile strength

- Tenacity

Tensile strength of fibre

it is the breaking of a fibre expressed as force per unit area

i.e. tensile strength= breaking strength/unit area(cross-section)

Its unit is lb/inch2. Also, It is usually used for cotton.

Tenacity of fibre

When a single fibre is being considered the breaking strength is termed tenacity.

Tencity= specific stress at break

Its units are grams/denier and grams/tex

“weight in grams of the 900-meter length of filament is grams/denier”

Weight in grams of 1000meter length of filament is grams/tex”

This strength is usually used for man-made fibres.

Elongation at break of fibre

When a fibre is subjected to force, it will stretch to a certain degree before it breaks. This stretching is termed elongation or extension. Hence is elongation when the fibre break.

Elongation at break%=extension in length /original length x100

The elastic recovery of fibre

When a fibre is stretched by a small amount it will return to its original position when it is released. The recovery depends upon the period of time for which it is held in a stretched position.

Stiffness of fibres

It is the ability of fibre to carry a load without deformation. It is expressed as grams/denier.

Toughness of fibre

It is the ability of a fibre to endure a large permanent deformation without rupture. It is expressed as grams/denier. This is larger than stiffness.

The specific gravity of fibre

It is the measurement of the density of fibre “It is the ratio of the mass of material to the mass of water at 40C.

Moisture content

It is the weight of moisture present in the material expressed as a percentage of the total weight

Moisture content = moisture Weight x 100/(total weight+moisture weight)

Natural fibre

Natural fibres are those which is provided by nature in a fibrous form such as cotton, wool, Silk, etc.

These fibres can be further subdivided into three main classes such as according to the nature of their sources.

- Vegitable fibres

- Animal fibres

- Mineral fibre

Vegitable fibres

Vegetable fibres include the most important of all textile fibres cotton, together with flax, hemp, jute and other fibres which have been produced by plants. They are based on cellulose, the material used by nature as a structural material in the plant world. The vegetable fibres are

- Bast fibres

- Leaf fibres

- Seed fibres

Bast fibres

Bast fibres are extracted from bark i-e the outer skin of plants. and the skin is taken from the stem of the plant. The bark is removed from plant skin and put in water and caustic soda is added to it for making it soft, after this it is mechanically crushed and also, and this process is known as the retting process. After this process fibres are taken out. such types of fibres are jute, ramie, flax, and hemp.

Jute fibres

It is obtained from the plant whose botanical name is carchorous capsularis and the second botanical name is carchorous oliterius.

Jute is grown generally in Bangladesh, Libia, India and Pakistan etc.

Colour white

cell diameter 12↔20 u(micron)

It has a broad lumen ( central cavity). These fibres are used for courser textiles, especially bags, sacks and carpet-backing.

Ramie fibres

It is a strong and soft fibre but has no elasticity. Also, Its botanical name is Boehmerianivea or Bochmeria tenacissema. Chiefly it is grown in China

Cell width 20↔30 u(micron)

Fibre length 0.5″ ↔7″

It has an oval-type lumen. It is used for making canvas, packing material, nets and sewing thread.

Flax fibres

It is a fine soft fibre. Its botanical name is “Genus linen” So it is known as linen

It is grown generally in the united states, Canada and Argentina. Also, its cross-sectional area is polygonal and its lumen is oval type.

Cell diameter is 15 ↔ 17 u(micron)

It is used especially in sailcloth and lent cloth, sewing threads, handkerchiefs, table cloth, sheets, collars, cuffs etc.

Hemp fibres

This is obtained from plants having the botanical name “Cannabis Sativa”. Its plants having a height of 10 feet are cultivated in European countries and also in Asia, Russia, Hungry Romania etc.

- Fibre length 6 feet,

- cells length ½ inch to an inch.

- Its cross-section is polygonal,

- Lastly, the cell is circular and cylindrical in shape.

It is used for coarse fabrics such as canvas, ropes, etc.

Leaf fibres

Leaf fibres are obtained from the leaves of the plants. These fibres are hard as compared to bast fibres, but some leaf fibres can be softer than bast fibres. It is divided further into two groups.

- Sisal fibre

- Abaca fibre

Sisal fibre

These are hard fibres and are obtained from the leaves of the plants. Also, its botanical name is “Aqave Sislana“. These fibres are grown generally in Indonesia, South Africa, Mexico and Cuba.

- Length of fibre 2 to 3 foot

- Cell wall diameter of 20 to 24u( micron) also has a length of 1 to 5 mm.

- These fibres are used basically in rugs, brushes, marine ropes and ladies’ hats.

Abaca fibre

These are hard fibres obtained from plants of abaca. Abaca plants are grown generally in the Philippines. Also, the length of fibres is 3 to 10 feet and creamy to brown in colour. Furthermore, in cross-section, fibres are polygonal with thin walls.

These are used in ropes and cordage and in making power transmission ropes.

Seed fibres

Seed fibres are very important in inducing cotton. These fibres like other plant fibres are also constructed mainly from cellulose. These are further subdivided into four classes.

- Bombax fibre

- Kapok fibre

- Coir fibre

- Cotton fibre

Bombax fibre

These fibres are obtained from the species of wild trees generally growing in India’s south coast and in Brazil. These fibres are smooth and hard and indeed cannot be spun. These are used basically for stuffing purposes such As pillows, mattresses, and gilts.

Coir fibre

These fibres are obtained from the shell of the coconut trees. Generally, these trees are grown in Sri-lank and India. Basically, these fibres are used for ropes, twines, brushes and for stuffing purposes.

Kapak fibre

These fibres are obtained from the balls of the Kapok, plant. Basically, these are grown in Indonesia, India and Malaysia. Firstly, their colour is white to brown. Also, these are inelastic and can not be used for making yarn. The following fibres have a length of nearly 1 inch and their cell diameter is 15 to 30 u(micron) used for stuffing purposes.

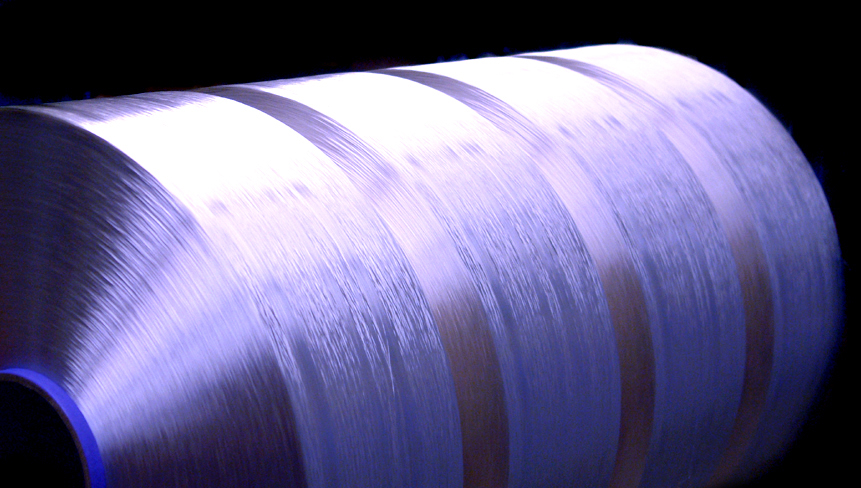

Cotton fibre

This is the most essential fibre in the classification of textile fibres. Basically, these fibres are obtained from cotton seed. Also, Its botanical name is “Gossypium“. Chiefly, this is found in tropical areas like Pakistan, India, China, Russia, Afghanistan, Mexico, the U.S.A, Egypt etc.

Fibre length 1 to 2.5 inches

Fibre diameter 12 to 17 u

Also, it is a lustrous fibre.

Uses

This is used for making shoes, clothes, carpets, fine suiting, curtains and also, many other purposes.

Fibres from animals

Animal fibres are the oldest in the classification of textile fibres, including wool and other hair-like fibres and also hair-like silk produced as filaments by cocoon-spinning creatures. Basically, these animal fibres are based on proteins(the complex material from which most of the animal body is made).

Rabbit hair

These are soft fibres in animal hair the classification of textile fibres. Basically, these are found in Australia and New Zealand. Also, Their cross-section is round, oval type and rectangular in shape. These fibres are up to 3-inch in length approximately. Also, their colour is white, brown or black.

Uses

Basically, It is used in making flats, knitting goods, gloves, Jerseys, and cardigan sweaters.

Camel hair

Presently It is found in China, Mongolia and the middle east(Saudi Arabia).

Properties

- Length 12 inches for Downey wools 1↔6 inches

- Diameter 10↔40 u

- The colour is pale red or brown.

- Cros-section of fibre is circular or oval type

- Crimps/ inch 5 or more

- Tenacity 16 grams/denier

- Elongation at break 39~45%

- Specific gravity 1.32

- Moisture regain 13%

These are used in overcoats, dressing gowns

Wool fibre

These are the natural fibres of animal origin in the classification of textile fibres. The wool is obtained from sheep hairs. These are also known as Keratin fibres(protein). Presently wool-producing countries are Pakistan, India, Kashmir, New Zealand, Australia, Spain, the U.S.A, South America, the UK etc.

Basically, keratin is a protein which is an amino acid compound linked with -CO-NH-. Also, these bonds are known as peptide bonds

The quality of wool depends upon these factors

- Firstly sheep breeding

- Secondly sheep food

- Also, grazing fields

- Lastly climatic conditions

Also, the wool obtained from sheep has qualities such as

- The best wool is obtained from sheep’s shoulders

- Head and back this gives medium wool

- Leg, tail, and Also belly are poor-quality wool.

Count of yarn for wool

One count =1 hank in one lb. i.e. No of hanks in one pound. it is the count of 2 hank means 2 counts.

1 Hank= 560 yards in one pond.

When the hank increases, the length of fibres increases as the count of the hank.

Fine wool

Fine wool has 60/s↔ 100/s

Courser wool

It has 36/s ↔44/s used for carpeting.

Properties of wool

Crimps

Crimps play an important role in the quality of wool, warmness is due to cramps. The measures of weave-ness are known as cramps. When more cramps it will be warmer.

The elasticity of wool is due to crimps

For fine wool 30 cramps/inch

Medium 5 ≥ 5 cramps/inch

Low less than 5 cramps/inch

Colour

White wool is good quality wool because it can be easily dyed and can be given any colour. While black and brown wool is lesser in quality due to bleaching and dying expensive processes.

Tensile strength

Wool has a tensile strength of 17000 29000 lb/inch2

Tenacity of wool

1.0 ~ 1.7 grams/denier

Elongation at break

25 ↔ 35%

Length of wool

Fine wool 1.5″↔ 5″

Medium wool 2.5″ ↔6″

Courser or long 5″↔15″

Diameter of wool

Fine wool 15↔17 u

Medium wool 24 ↔34 u

Courser wool 34 ↔40 u

Moisture absorption 16 ↔18%

Specific gravity 1.32

Uses of wool

Basically, used in garments, suiting, shells, sewing animaters etc. Rough wool is used in carpets and rags.

Silk fibre

These are animal fibres in the classification of textile fibres. It is protein fibre also called “fibroin“. Identically, they are linked with peptide bonds. Wool contains sulphur but silk has no sulphur. Overall, the industry is based on silk-worn which is an insect. Presently most of the silk industry is in Japan, China, Korea, European countries, Turkey, India, Pakistan, Spain etc.

Basically, there are two types of silk

Wild silk: It is called Bomaxmori.

Tussah silk; is in India and Pakistan.

Properties

- The cross-sectional structure is irregular

- Diameter 0.0005″ ↔007″

- The colour is creamy to yellow

- Tenacity 3.5 ↔ 5 grams/denier

- Elongation at break 20 ↔ 28%

- Specific gravity 1.25

- Moisture regain 11%

- The structure is oxalline crystalline may be (xylene)

Uses

Basically, it is comfortably used in summer. So it is used for making ladies’ suits and wedding dresses. Also, pure silk is very expensive.

Asbestos or mineral fibres

Mineral fibres are of limited importance in the textile trade and in the classification of textile fibres. Asbestos is the most useful fibre in this class. It is obtained from rocks. These fibres are packed tightly together like wool. Also, these are inflammable and heat resistant. It is found in China, India, Pakistan, Canada, South Africa and Russia.

Above all, asbestos consists of severed natural minerals like Mg, iron, calcium magnesium silicates iron sodium silicates.

- These are long flexible light blue in colour

- Length of fibre 3″↔4″

- Silky lustre is also green to brown in colour.

- Spinning is difficult, it is done by mixing other fibres such as my nylon, and glass, length of the fibre is ½”↔ 12″ or more.

- The surface is smooth and the regular cross-section is semicircular or polygonal. Also, molecules of asbestos material are arranged in the form of curved sheets which build up cylinders from the tubes.

- It is not affected by acids, alkalis and other chemicals.

Uses

It is used in brick linings, leathers of motors, gas shirts, conveyer belts, Industrial packing, and furthermore fire proof clothing. Also, electrical insulation clothes.

Classification of man-made fibres

Classification of man-made fibres is in the next post