Cotton fibre terms

By all means, the raw material is very important for good quality yarn. The following cotton fibre definitions are very important

- Length

- Uniformity

- Short fibres

- Strength

- Elongation

- Fineness

- Maturity

- Color and color grade

- Also, trash

Fibre length

The first and most important cotton fibre definition is length. So, the length of fibre is measured in different ways. Hence, normally called staple length.

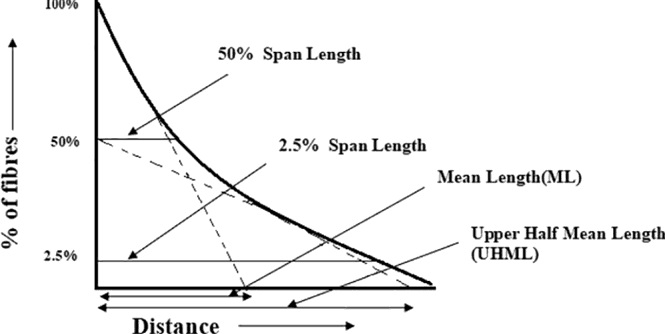

Span length 2.5% (SL 2.5%)

(by ICC Mode)

Basically, the length of longer 2.5% fiber extended from the fibrous strand. The optical sensor of the fibro graph scans the randomly arranged stand of fiber until 2.5% of the fibers are counted and given as S.L 2.5%. Also, the greater the value better spinnability, yarn evenness, strength, luster, and hairiness.

Sapin length 50% similarly measured the length of longest 50% fibers is termed as span length 50%

| Span length 2.5% | |

| Under 20.5mm(3/16”) | Short |

| 20.5mm(3/16”) to 25.4mm(1”) | Medium |

| 1 1/32”(26.2mm) to 1 3/32”(27.8mm) | Medium long |

| 1 1/8” (28.6mm)to 1 5/16”(33.3 mm) | Long |

Upper half mean length (UHML)

(HVI mode)

UHML is the average length of the upper half of the longest fibers when measured on a weight basis i.e. average length of the longest fibers.

i.e. Mean length (ML)

HVI mode

Mean length is the average length of all fibres in the test specimen based on weight length data

- A span length of 2.5% is the basis of the drafting roller setting. it is a reference to the shortest distance between roller nips so that a few fibres are broken at this length. Normally S.L 2.5% is the setting distance but some technicians tend to set the roller gauge as (10+SL2.5%) mm as the best value.

- Also, a span length of 50% is a more valuable parameter for determining spinning performance and yarn quality.

- Altogether, a span length of 67% is considered the average length of the fibre and a greater value shows a strong increase in yarn.

Relationship between span length of 2.5% and UHML

Since the span length is measured in ICC mode and UHML is measured in fibre length in USDA HVI mode. Generally, both are measures of the longest fibre length in cotton.

Normally UHML is 0.040~0.080″ higher than the span length of 2.5%

Relationship between span length 50% and mean length ML

The mean length of a fibre measured in USDA HVI mode is 0.4~0.5″ higher than 50%span length. Since the calculation of both methods ICC and HVI (USDA) is different entirely, there is no way to convert any length result between them.

So, to properly understand see the fibro graph and two different theories of length calculation

Uperhalf mean length (UQL)

(by AFIS)

Basically, 2.5% fibres measured by AFIS individualizer is termed as UQL.

Thus length calculation per ICC mode

i.e. ICC =international cotton calibration

Also, 100% is considered zero

i.e. length calculation in USDA mode

i.e. USDA = United States Department of Agriculture

(Called also HVI mode)

HVI spectrum standards

Upper half mean length

| Less than 0.99″ | Short |

| 0.99~1.10″ | Medium |

| 1.11~1.26″ | Long |

| Above 1.26″ | Extra long |

Uniformity index

| Less than 77 | Very low |

| 77~80 | Low |

| 81~84 | Medium |

| 85~87 | High |

| above78 | Very high |

Short fibre index

| Less than 6 | Very Low |

| 6~9 | Low |

| 10~13 | Medium |

| 14~17 | High |

| 18~above | Very High |

Strength GPT gram/tex

| Less than 21 | Very weak |

| 22~24 | Weak |

| 25~27 | Medium |

| 28~30 | Strong |

| 31 ~above | Very strong |

Following here are other cotton fibre definitions,

Uniformity

It is measured variation of length i.e. how much uniform distribution of fibre lengths, in fibrogram.

Uniformity ratio (UR%)

Basically, the uniformity ratio between span length is 50% and span length 2.5% expressed as a percentage. So, a higher value indicates there are lesser short fibres and more regularity in length. As a result, the better the value better is spinnability.

i.e. U.R%= S.L 2.5%/S.L 50%x100

Uniformity Index (UNF) UI

Basically, it is the ratio of mean length to UHML and is a measure of fibre uniformity in the sample expressed as a percentage. Thus UNF is expressed as

i.e. UI= M.L/UHML x 100

i.e. ratio of the average length of all fibres to the average length of the longest fibres. Altogether, lesser value makes processing more to lower the quality of the product.

Relationship between UR% and UI

Generally, there is no confirmed relationship between the two parameters. So,

i.e. UI= 1.80 x U.R% or UI = 1.70x U.R%

Short fibres

Those fibres which are shorter than half of the fibre length are called short fibres

Short fibre index (SFI)

By ICC mode, By HVI mode

SFI is a value that is calculated using a sophisticated algorithm. Also, the fibro gram is mathematically converted to a length distribution curve. Thus SFI is an indication of the number of fibres (%) that are less than 0.5″ or 12.7mm in length. So it correlates very well with AFIS SFC(w).

Short fibre content (SFC)

By AFIS

SFC is the percentage of fibres less than 0.5 inches by weight. Generally, AFIS measures SFC(w) and SFC(n).

In most spinning cases short fibres percentage by weight is considered but SFC by number is also important because it is believed that the number of short fibres is more important than weight.

Floating fibre percentage (FF)

As can be seen, those fibres which are not in control of drafting rollers are considered floating fibres. Thus, these fibres tend to deteriorate drafting. At this point, resulting in thick & thin places. Also, as low the percentage it better will be drafting and spinnability.

The floating fibres percentage can be calculated as

Hence, FF %age ={S.L2.5%/(S.L50%-0.075)2-1}X 100

Similarly in HVI mode and AFIS.

Floating fibre index

Hence, FFI=(UHML/ML-1)X 100

Also, FFI =(UQL/ML-1)X 100

Strength

Pressley is the fibre bundle strength expressed in thousand ponds/inch2 while GPT is the breaking tenacity of fibres in grams per tex. Furthermore, good fibre strength results in better yarn strength.

A 1/8″ clamp is generally used to measure strength when a 1/8″ clamping distance is used fibre break at weak points and with a 0″ clamp they break with more force thus 1/8″ clamp gives correct results.

If you are using HVI then it will automatically give you a GPT value.

With stelometer ICC mode.

Hence, gram/tex=breaking load in kg/mass in milligram x 14.9

Also, Presslay= Break load in kg/mass in milligrams x 64.368

Also, P.I=breaking load in ponds/ milligrams.

Hence, exactly gram/tex= P. I X 6.8

| Strength ponds/ inch2 x1000(PSI) | |

| 75~80 | low |

| 81~85 | Average |

| 86~90 | High |

| 91 and above | Very high |

Elongation percentage

The extent to which fibres bundle elongate before breaking. Lesser value results in poor strength and more value results in imperfections, so optimum value is required.

Fineness and maturity

Micronair is the measure of fiber’s linear density i.e. weight per unit length of fibers is called fineness of fiber. (Also called microgram per inch). It is also expressed as tex, dtex, or milli-tex. Finer fiber gives more surface-to-weight ratio and are more flexible in terms of fabric drape and feel compared with thick fibers

The degree of secondary wall development of cotton fiber is termed the maturity of cotton. Hence, a cotton fiber with 50~80% secondary wall developed is considered as mature, 30~40% immature and below 25% dead cotton. Thus the ratio between mature and dead cotton is called the maturity ratio. Thus technically

Fibre with more than 0.5 circularity/ fibre with 0.25 circularity

Also, the maturity and fineness of cotton are very important for yarn spinnability, the strength of the fabric, and dying. Fibers with lesser micronair value are usually unripened with lesser maturity and result in poor strength, more hairy yarn, neps formation poor quality yarn, Also immature fiber causes varying yarn dyeability and white spots

Similarly, course fibers are not suitable for the fine count due to the lesser number of fibers in the yarn cross-section. Also, the normally good range is 4.0~4.8 mice and 0.9 ~0.95 maturity

Immature fibre content ( IFC percentage)

Fibre with less maturity is very bad for yarn quality. thus fibre with 0.25 circularity is called immature fibre and %age is termed IFC %. The value of IFC should also be as low as possible.

i.e. IFC< 5.0%

Neps count per gram

Immature fiber results in the formation of entangled knots of fibres termed nep. Hence, the number of these entangled knots per gram of fiber sample is called nep count/gram i-e lesser neps better will be imperfections.

Elongation

| Less than 5.0 | very low |

| 5.0~5.9 | low |

| 6.0~6.7 | medium |

| 6.8~7.6 | high |

| 7.7~above | very high |

Micronair

| Less than 3.0 | Very fine |

| 3.0~3.6 | Fine |

| 3.7~4.7 | Medium |

| 4.8~5.4 | Course |

| 5.5~above | Very Course |

Maturity index

| Less than 0.75 | Very immature |

| 0.75~0.85 | Immature |

| 0.86~0.95 | Mature |

| Above 0.95 | Very mature |

Neps/gram

| Less than 100 | Very low |

| 101~200 | Low |

| 201~300 | Medium |

| 301~450 | High |

| Above 450 | Very high |

Above all spinning cotton fiber definitions, need to be understood before running fiber.

Trash

It is measured as the amount of non-lint materials in cotton, such as leaf and bark from the cotton plant

Instruments used for classing/grading cotton

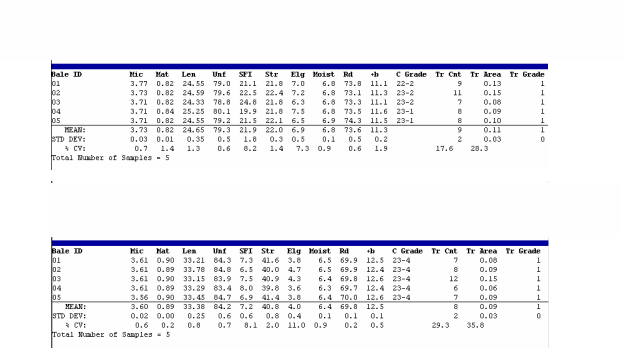

HVI

High volume instrument measures (HVI) trash or non-lint content by using cameras, made by Uster technologies. The increasing number of fibre measurement trends is provided to a set of instruments that can be analyzed on the computer and can print results. HVI measure the most important fibre classing/grading properties that are high throughput results in spinning mills.

The trash is measured by using a video camera while micro-nair is measured by using air flow through the sample and the remaining parameter is measured by fibrograph. The system is capable of measuring 180 samples per hour.

The following characteristics can be measured by using an HVI instrument.

| HVI Spectrum measurement | ||

| i | Spinning consistency index | SCI |

| ii | Micro-naire | Mic |

| iii | Maturity index | Mat |

| iv | Upper half mean length | Len |

| v | Uniformity index | Unf |

| vi | Short fibre index | SFI |

| vii | Strength | Str |

| viii | Elongation | Elg |

| ix | Moisture | Moist |

| x | Reflectance | Rd |

| xi | Yellowness | +b |

| xii | Colour grade | CG |

| xiii | Trash count | Tr Cnt |

| xiv | Trash area | Tr Area |

| xv | Trash grade | Tr Grade |

| xvi | Fluorescence | UV |

| xvii | Neps | Nep |

AFIS

An advanced fiber information system is used to measure special neps in cotton. There are modules one measures the number of neps and the second one is used to measure the length and fibre diameter. This device works on aero-mechanical principles.

The following characteristics of fiber can be tested by using this instrument.

| AFIS measurement | ||

| i | Fiber length | L(w) & its CV% |

| ii | Upper quartile length | UQL(w) |

| iii | Length(by number) | L(n) & its CV% |

| iv | Short fibre content | SFC(n) |

| v | Short fibre content | SFC(w) <0.5% |

| vi | Fibre length 2.5% | UQL 2.5% |

| vii | Fibre length 5% | UQL 5% |

| viii | Fine mtex | F mtex |

| ix | Immature fibre content | IFC% |

| x | Maturity ratio | Mat ratio |

| xi | Neps (diameter) | Nep(um) |

| xii | Neps (number) | Ct/gram |

| xiii | Seed coat neps(diameter) | SCN(um) |

| xiv | Total neps | Cnt/gram |

| xv | Nep mean size | Mean size |

| xvi | Dust | Dust Cnt/gram |

| xvii | Trash | Trash Cnt/gram |

| xviii | VMF% | VMF% |

Frequently Asked Questions

What is UHML?

UHML is the average length of the upper half of the longest fibers when measured on a weight basis i.e. average length of the longest fibers. Since the span length is measured in ICC mode and UHML is measured in fiber length in USDA HVI mode. Generally, both are measures of the longest fiber length in cotton.

What are UHML and UI?

The HVI ( high volume instrument) measures two traditional length parameters, UHML (Upper half mean length ) and UI (Uniformity index). The mean length ratio to UHML is a measure of fiber uniformity in the sample expressed as a percentage. Thus UNF is expressed as

i.e. UI= M.L/UHML x 100

i.e. ratio of the average length of all fibers to the average length of the longest fibers. Altogether, lesser value makes processing more to lower the quality of the product.

What does UHML mean?

What is the full form of Uhml cotton? UHML is the abbreviation of the upper half mean length. The UHML is the length of the upper half of a longer fiber when measured length on a weight basis in a specimen. This parameter is based on weight basis, not on length UHMLw. In other terms, it is the average length measured by weight of one-half longer fibers when divided by weight.

What is 2.5% Span length?

The length of 2.5% fiber extended from the fibrous strand. The optical sensor of the fibro graph scans the randomly arranged stand of fiber until 2.5% of the fibers are counted and given as S.L 2.5%. Also, the greater the value better spinnability, yarn evenness, strength, luster, and hairiness.

What is the uniformity of cotton fibers?

What is the uniformity ratio UR%? Uniformity of cotton is measured by variation of length i.e. how much uniform distribution of fiber lengths, in fibrogram. the uniformity ratio between span length is 50% and span length 2.5% expressed as a percentage. So, a higher value indicates there are fewer short fibers and more regularity in length.

What is the upper half mean length?

What is the upper half mean length of cotton? The upper half mean length (UHML) is the average length of the upper half of the longest fibers when measured on a weight basis i.e. average length of the longest fibers. Since the span length is measured in ICC mode and UHML is measured in fiber length in USDA HVI mode. Generally, both are measures of the longest fiber length in cotton.

What is GPT in cotton?

What is gram per Tex? What is cotton fiber strength? Pressley is the fiber bundle strength expressed in thousand ponds/inch2 while GPT is the breaking tenacity of fibers in grams per tex. Furthermore, good fiber strength results in better yarn strength.

What is the difference between HVI and AFIS?

HVI stands for high volume instrument that measures trash or non-lint content by using cameras, made by Uster Technologies, including fiber length, length uniformity, bundle tenacity, elongation, micronaire, color, and trash content. AFIS Advanced fiber information system is used to measure neps in cotton. There are modules one measures the number of neps and the second one is used to measure the length and fibre diameter. This device works on Aero-mechanical principles. It measures complete length and diameter distribution, trash content, nep content, fineness, and maturity. The detailed parameters are in the section Classing and Grading of Cotton.

What is the fineness of fiber?

What is the fineness of cotton fiber? Fineness is the measure of fiber’s linear density i.e. weight per unit length of fibers. (Also called Micronair, microgram per inch). Also, the number of fiber per 1000 meters is desi-tex. It is also expressed as tex, dtex, or milli-tex. Finer fiber gives more surface-to-weight ratio are more flexible in terms of fabric drape and feel compared with thick fibers.

What is micronaire in cotton?

Micronair is the indication of fiber cell thickness used to indicate fiber fineness and maturity of cotton. It is the measure of airflow through a compressed cotton sample. Also, the maturity and fineness of cotton are very important for yarn spinnability, the strength of the fabric, and dying. Fibers with lesser micronair value are usually unripened with lesser maturity and result in poor strength, more hairy yarn, neps formation poor quality yarn, Also immature fiber causes varying yarn dyeability and white spots.