In the structure of the cotton fibre, each fibre develops as slight swelling of the epidermal layer of the surface of the seed inside the ball. Each swelling develops into a hollow tube and increases in length daily till it reaches its entire length. Up to this stage which is nearly half of its growth cycle the fibre is hollow and consists of the primary wall. In the second stage of fibre development, secondary layers of cellulose are deposited on the inside of the primary wall daily. Once such a layer is deposited each day in the form of reversal spirals. Sweller cross-section of the fibre shows daily growth of rings of 0.2-micrometre thickness. Those rings are caused by differences in cellulose structure between day and night. If cotton is grown under constant artificial light rings are not formed.

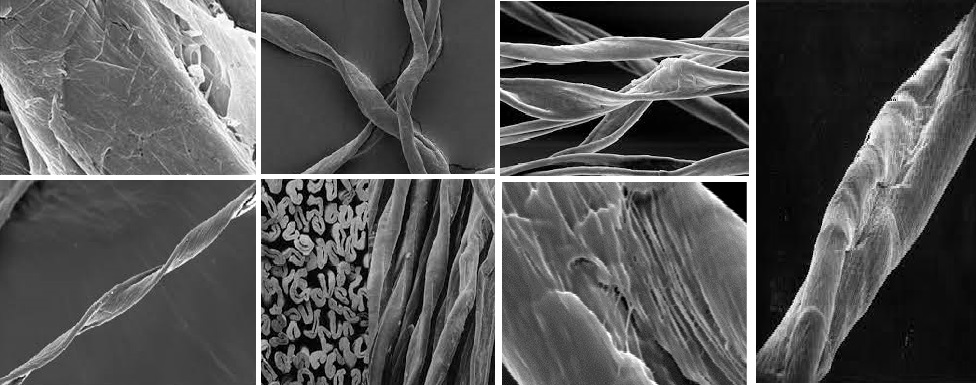

Longitudinal structure of the cotton fibre

Long-length cotton fibre appears as a ribbon-like strand with twist and reversal or a collapsed twisted tube. However, its length is 1/2″ to 2″ and its thickness is around 3~15 microns depending upon its variety and climate condition. A large number of convolutions usually 60 per centimetre are found. The twist in fibre is called convolution. These convolutions give an uneven surface to fibre, causing friction of fibre which give adequate increase strength in spun fibre. Flat twisted ribbon but has a lower number of convolutions also looks like in immature cotton. longitudinally mature cotton fibres have three parts.

Base/root

It is a short fragile coned-type portion which during the growth of fibre remains constant, in the epidermal of seeds. It is broken in ginning process and rarely found in commercial cotton fibres

Body

This is the main portion of cotton fibre about 3/4 of the total length. It has the same diameter throughout and has thick walls and narrow Lumen.

Tip

It is a straight narrow portion at the end of the fibres about 1/4 of the fibre length. It is very small in diameter.

The cross-sectional structure of the cotton fibre

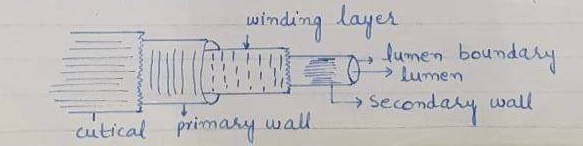

Cotton fibres have a structure which is studies for nearly a century also, which is shown as multilayered. The structure consists of the primary wall (cell) of the cotton fibre, and the outer surface layer (the cuticle) particularly, has a large influence on fibre properties. Cotton fibre has a fibrillar structure which also consists of a primary wall, a secondary wall and a lumen. cross-sectional cotton fibre has the following parts as shown in Fig

Cuticle

Mature cotton fibre contains the following outermost layer of waxy which may also contain pectin and proteins material. It serves as a smooth water-resistant coating and protects the rest of the fibre. Basically, this layer is need to be removed from the fibre by scouring

Primary wall of cotton fibre

Firstly it is the waxiest material which is formed in the early days of growth during the first 15–18 days of fibre growth. It mainly consists of cellulose but also contains pertinacious and protein material. So, the deposition of the latter begins at a very early stage, possibly on the first day of growth

Winding layers

As can be seen in Fig, it is the first layer of the secondary wall and differs somewhat in structure from the primary wall and the remaining is of the secondary wall.

Secondary wall of cotton fibre

If we see the structure of cotton fibre as in Fig, it consists of layers of cellulose and also each layer forms a concentric sheet known as a daily growth ring. Basically, secondary layer of cellulose is in the form of highly crystalline fibrils and microfibrils. Also, fibrils and microfibrils are extremely thin needles which spiral around the fibre axis. Basically, the secondary wall represents 90% of the total weight of fibre.

Lumen wall

As can be seen, this is the boundary wall of the cavity portion inside of the fibre. After the secondary wall in the cotton fibre structure next is the lumen, the hollow canal which carries nutrients during growth. Also, contain the dried-out protoplasm and nucleus when cotton ball development is completed.

Lumen

It is the central cavity inside the fibre and is highly irregular in both size and shape. Also, it contains solid matter remaining from dried protoplasm cells.

Cellulose microfibrils

The primary structural component of cotton fiber is cellulose. Cellulose is a long-chain microfibril called polysaccharide made up of glucose units, arranged in crystalline form. These microfibrils are highly organized and contribute to the fiber’s tensile strength.

Lignin

In mature cotton fibers, lignin may be present, especially in the outer layers. Lignin is a complex polymer that provides additional support and rigidity to the fiber. Also, cotton fibers have distinctive surface grooves or twists, known as convolutions. This surface convolution features a high surface area which enhances absorb the ability of moisture and dyes.

Mucilage (in immature fibres)

In immature cotton fibers, mucilage is a layer of surrounds the cellulose core. It is aid in seed dispersal and protection. During cotton processing, this mucilage is removed.

The unique combination of cellulose, lignin, and other components in the cotton fiber’s structure gives it the desirable properties of softness, strength, breathability, and absorbency. These properties have made cotton one of the most widely used natural fibers for textiles and various industrial applications

Chemistry of cotton fibres

Chemical composition of cotton fibres as a blow

| Cellulose | 80-85% |

| Nitrogenous material | 1~2.8% |

| Oil and waxes | 0.5~1% |

| water | 6~8% |

| Pectic material | 0.4~1% |

| Colour Pigment | 3~5% |

| Minerals | 0.8~1.8% |

Degree of polymerization

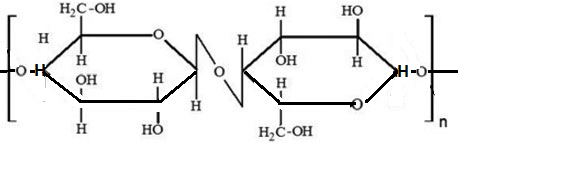

After scoring cotton fibre 99% of cotton is cellulose. Cellulose is a polymer made up of long chain molecules linked together with a carbon-oxygen bridge after eliminating water also called a glycol bond. Basically, there is the anhydrous bridge of the cellulose unit to form a polymer chain. So, this repeating unit of cellulose is called “degree of polymerization“.

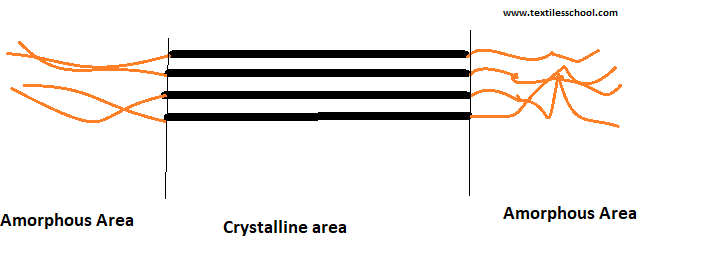

Degree of crystallinity

Other cellulose-containing cellulose (e.g. wood pulp) is different from cotton cellulose as constructed polymer. Cotton cellulose is different from wood pulp as having a high degree of crystallinity and a high degree of polymerization. So, the “degree of crystallinity” is how closely packed and parallel molecules of cellulose one.

Altogether the high degree of crystallinity and polymerization indicate the high strength of fibres. Also, in cotton, the cellulose chain is held by hydrogen bonding. So, these hydrogen bonds occur between the hydroxyl group of adjacent molecules and parallel and closely packed molecules in the crystalline area of cellulose.

Reactive hydroxyl group of cotton fibre

Hence you can see the picture above, In the structure, three molecules of hydroxyl group, one in primary and two in secondary in each repeating unit of cellulose make it more chemically reactive. So, the groups undergo a reaction with dyes and in finishing result in modified cellulose fibre. Also, these hydroxyl groups serve to absorb moisture for water molecules. Water is chemisorbed on direct hydrogen bonding and a hydroxyl group.

In regenerated generally, the strength of cellulose fibre decreased with an increase in moisture content but can cotton fibre strength increased with an increase in moisture content. This difference is due to cellulose inter molecule bonding and the degree of crystallinity

| Degree of crystallinity and polymerization of fibre(cellulose) | ||

| Fibre | The average degree of polymerization | The average degree of crystallinity% |

| Cotton | 9000~15000 | 73 |

| Wood pulp | 600~1500 | 35 |

| Viscose Rayan | 250~450 | 60 |

| High tenacity | 500~650 | |

Thermoplastic fibre melts during high temperatures resulting in brittle and glass transition at some point below the melting point. Also, at glass transition temperature thermoplastic becomes brittle and loses its elasticity. So on the opposite, cotton fibre doesn’t melt like thermoplastic fibre and remain very flexible at very low temperature. Also at high-temperature cotton fibre decomposes instead of melting. Long exposure to dry heat of 300 0F(1500C) will result in fibre start decomposing slowly but exposure to high dry heat of about 4000F(2500C) causes rapid decomposition.

cotton Pre-treatment

Cotton pretreatment refers to the numerous processes applied to cotton fibres before they go through further treatments, similar to printing, dyeing, or finishing. The main objective of pretreatment is to update the cotton fibres to get desired characteristics and improve the overall quality of the final textile product.

Pre-treatment of cotton has key benefits such as overall quality parameters and performance benefits, also,

- Improved absorbency

- Enhanced dyeability

- Increased fabric uniformity

- Fabric drape

- Improve strength

Bleaching

Cotton fibres have or stains natural color variations. This stain need to remove to achieve a sweet-sounding whiteness. Bleaching agents used are hydrogen peroxide or sodium hypochlorite, to remove the stains and natural color pigments. Since, resulting in a uniform and brighter fabric.

Scouring

Removal of dirt, natural residual chemicals, oils, waxes such as impurities/ contaminations. This process is called scouring. The process involves treating the fabric with alkaline solutions or surfactants. To ensure the cotton is thoroughly cleaned is done rinsing.

Mercerization

Mercerization is process to enhance luster, dyeability and strength of cotton fibres. This process involves treating the fabric with a strong alkali solution. So under controlled tension typically sodium hydroxide. This process allow cotton fibres to swell. Also, resulting in improved properties and increased surface area.

.