All textile materials are less or more hygroscopic and have moisture relations in textiles. Also, they contain a certain amount of moisture which depends upon the relative humidity of the surrounding air atmosphere. They will absorb moisture, in a damp condition and they will give up moisture in a dry atmosphere. Therefore it follows that weight will vary with the R.H. of the surrounding atmosphere. Hence properties of the material will be affected. The following properties vary with the amount of moisture

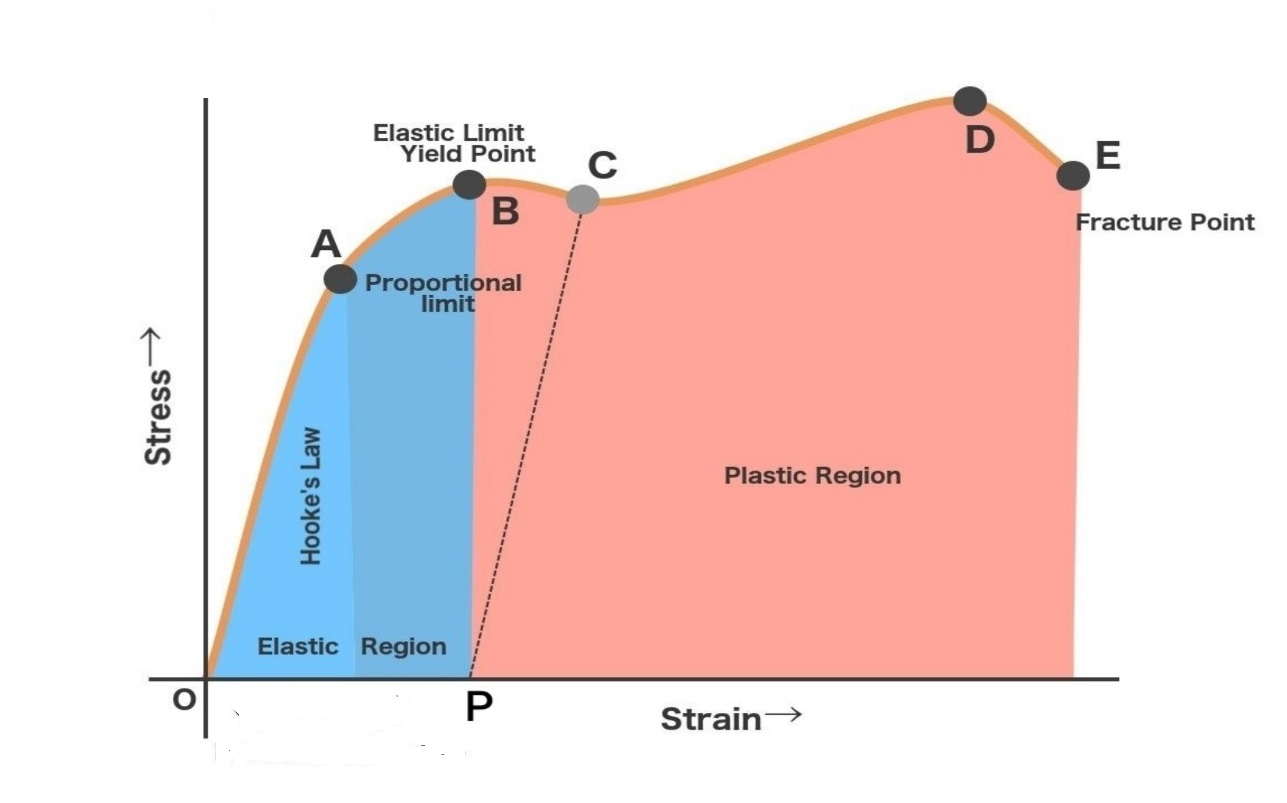

- Mechanical properties of fibers

- Electrical behavior

- Elasticity and strength

- Yarn rigidity and hairiness etc

Hence moisture present in textiles is very important, especially from the following point of the view

Moisture in textiles at purchasing

At purchasing time, money is paid accordingly to the weight of the material which highly depends on the moisture present in the material. So the buyer must know the moisture weight in the material otherwise he may face a loss of money. Standard regain of different materials is given blow material

| Fiber type | Moisture content % |

| Cotton | 8.5 |

| Wool | 17 |

| Viscose | 11~13 |

| Silk | 11 |

| Jute | 14 |

| Polyester | 0.3~0.4 |

| Nylon | 4.2 |

Moisture relation for textiles processing point of view

With respect to processing, moisture plays a very important role. It must be nearly standard as given blow

| Department | Moisture % |

| Mixing | 7 ± 0.5 |

| Lap/ chute feed | 5.5 ± 0.5 |

| Silver | 5.5 ± 0.5 |

| Roving | 5.5 ± 0.5 |

| Ring | 5.0 ± 0.5 |

| Winding | 6 ± 0.5 |

| Packing | 8.5 ± 0.5 |

More moisture results in the poor opening, neeps, overlapping of rollers, and also the rusting of metallic surfaces may occur. At roving and ring end breakage rate increases and straightening and parallelization decrease

Less moisture in the material results in fiber breakage and damage.

Effect on yarn quality

The strength of fibers increases in the case of cotton and decreases for other fibers when moisture is increased. Also, low moisture results in lint loss, and unnecessary wastage increases.

Some definitions of moisture in fibers

Original weight

“Weight of material in its original condition containing any moisture level”. It is denoted by O.W

Dry weight

“The weight of the material without any moisture is called dry weight”. It is denoted by D.

Oven dry weight

“Weight of material dried at oven state i.e. at 1050C”. It is also called bone dry weight.

Moisture regain

“Weight of moisture based on the dry weight”. It is denoted by R

Moisture content

“Weight of moisture based on original weight”. It is denoted by M.

M.R = W/D

M.C = W/(W+D)

or

R = W/D x 100

M = W/(W+D) x 100

Where R and M are M.R and M.C, expressed in percentage. Also,

M = W/(W+D) x 100

= (W/D)/(W/D + D/D) x 100 = (R/100)/(1+R/100) x 100

or M = (R/(100+R)) x 100

Similarly

R = (M/(100-M)) x 100

From the above relations, it is quite clear that R is always greater than M.

Correct condition weight ( correct invoice weight)

weight of material at an 8.5% moisture level ( for cotton fiber) is called invoice weight. Setting and purchasing are done on the basis of this weight. Corrected condition weight is equal to oven dry weight plus standard regain.

i.e. corrected condition weight (C.C.W) = dry weight + dry weight x 8.5/100

= D(100+R)/100

Absolute humidity

“The weight of water in a unit volume of air, ” i.e. gram/m3, etc.

Relative humidity

The ratio between actual vapor pressure to vapor pressure at saturation is expressed in percentage.

R.H% = actual water vapor pressure/vapor pressure at saturation

From the hygrometer we measure R.H

i.e.

R.H = 98.6-(dry temperature-wet temperature weight)/dry temperature x 100

Moisture hysteresis

In the desorption process, at any given relative humidity, a wet fiber material retains more moisture compared to this can adsorb. This moisture absorption difference at the same relative humidity in the desorption and adsorption curves is called hysteresis.

The sorption hysteresis phenomenon is well-known for wood to understand. Also, hysteresis means the equilibrium moisture content (EMC) is due to differences in the adsorption and desorption processes.

Count

To distinguish between fine and coarse strands of fiber, yarn is given the size number called the count. There are two major systems of yarn count i.e. direct and indirect systems.

Direct system of yarn count

The length is constant and the weight is variable i.e. weight per unit length.

Tex count

The weight in grams of 1000 meters gives a count

Tex = grams/kilometer

Tex is also considered a linear density. smaller units such as milli-tex are also in use. Also times deci tex and kilo-tex are used. i.e.

1 tex = 1 gram /km

As, 1 mtex= 1 milligram/km

1 k-tex = 1 gram/1 meter or 1 kg / 1 km

Denier count

It is defined as “weight in grams of 9000 meters of yarn”

i.e. denier = gram /9000 m

Grex count

Weight in grams of 1000 meters

i.e. grex = grams/10000 m

Indirect system of yarn count

The weight is constant and the length is variable. i.e. ( length per unit weight )

English count/ Nec

The number of hanks which weigh 1 pound ( lb). it is denoted as Nec.

Count = hanks/lb

Cotton hanks = 840 yards

Worsted hank = 560 yards

Linen hank = 300 yards

Silk hank = 840 yards

Metric count

The number of hanks giving 1 kg weight. where hank = 1000 meters.

Thus metric count = hanks/ kg

Some conversion of count

English x tex = 590.5

English x denier = 5315

Denier = tex x 9

Grex = tex x 10

Matric = 1.0693 x English count

i mon = 82 lbs = 40 kg

1 lb = 7000 grains

= 453.6 grams

= 16 ounces( oz)

1 kg = 2.02046 lbs

1 oz. = 437.5 grains

i gram = 15.43 grains

1 m = 1.0936 yds = 39.37 inches

Count Nec= 8.33 x length (L) / weight(W)

i.e. Nec =64.8/weight in grams

where L= length , W= weight

Problem-solving regarding moisture in textile

Q1

The oven-dry weight of 500grams of cotton was found to be 400 grams, calculate

- Weight of moisture

- Moisture regain and its %age

- Moisture content and its %age

- Conditioned weight of cotton

Solution (1)

D.W = 500 grams

D= 400 grams

W=500-400 =100 grams

M.R =W/D = 100/400 =0.25

R= W/D x 100 = 100/400 x100 = 25%

M.C = W/O.W = 100/500 =0.20

M= W/O.W x 100 = 100/500 x 100 = 20%

C.C.W = 400+400×8.5/100 = 434 grams

Q2

Moisture regains of cotton was found to be 10.5% which will be the level of moisture content.

Solution (2)

R = 10.5%

M = (R/(100+R))x 100

= (10.5/(100+10.5)) x 100 = 9.5%

Q3

The consignment of 400 kg of cotton yarn was despatched to a station, where oven dry weight of 1 kg sample was found to be 800 grams. Calculate the conditioned weight of cotton ( C.C.W ) for which is to be paid by the consigne. Also, calculate R & M values and excessive M.R.

Solution (3)

O.W = 400 Kg

1Kg material has a dry weight = 800 grams

400 Kg material has a dry weight = 800/1000 x 400

Or D = 320 kg

W= 400-320 = 80kg

C.C.W = 320 + 320 x 8.5/100

= 347.2 kg

R = W/D x 100 = 80/320 x 100 = 25%

M = W/O.W x 100 = 80/400 x 100 = 20%

Excessive regain = 25-8.5 = 16.5%

Q4

A warper beam of cotton yarn contains 500 ends also, and each end has a length of 3500 yds. The yarn contains moisture up to the extent of 5% above the C.C.W and its weight is now 100 lbs. Calculate the count of yarn on dry weight, C.C.W, and present count.

Solution (4)

No. of ends =500

Length of each end = 3500 yards

Length of ends= 3500 X 500/840

=2083.34 hanks

Present count = no. of hanks/lbs

= 2083.34/100 = 20.83s

At 5% excess moisture, moisture present will be 13.5%.

Hence,

113.5 lbs material has dry weight = 100 lbs

100 lbs material has dry weight = 100/113.5 x 100

= 88.10 lbs

Count at dry weight = 2083.34/88.10 = 23.65s

C.C.W = 88.1 + (88.1 x 8.5/100)

= 95.59 lbs

Hence, count at C.C.W = 2083.34/95.59 = 21.8s

Q5

A representative sample of 9.5 oz drawn from a consignment of 1200 lbs cotton gave the oven dry weight of 8.5 oz. Determine the correct invoice weight of the consignment and the amount of money to be paid by the purchaser, if the price per pound of cotton is USD dollar 0.9.

Solution (5)

Total weight = 1200 lbs

Sample O.W = 9.5 oz

sample D.W = 8.5 oz

Moisture weight W= 9.5-8.5 = 1.0 oz

9.5 oz material has moisture = 1.0 oz

1200 Lbs material has moisture = 1 x 1200/9.5

= 126.31

Dry weight D.W = 1200 – 126.31

= 1073.68 lbs

C.C.W = 1073.68 + ( 1073.68 x 8.5)/100

=1164.95 lbs

Hence money to be paid =1164.95 x 0.9

=1048.455 $

Q6

A sample of cotton yarn is wrapped & count is in the 40s. A certain amount of moisture has been added and the count becomes 38s. What percentage of moisture has been added?

Solution (6)

Count = number of hanks/lbs

Hence,

40s weight = 1/40 = 0.025 lbs

38s weight = 1/38 = 0.0263 lbs

Moisture weight = 0.0263-0.025

= 0.0013157 lbs

Percentage of moisture added = 0.0013157/0.025 x 100

= 5.26%

Q7

A spindle point yarn of the 40s contains 5% moisture. What will be the count of yarn when moisture is added becomes 8.5 %, Which is the standard moisture?

Solution (7)

Weight of yarn =1/40 = 0.025 lbs

Excess moisture added = 8.5-5 = 3.5%

C.C.W = 0.025 + ( 0.025 x 3.5) /100

= 0.025875 lbs

Hence, Count = 1/0.025875

= 38.65 S

Q8

Calculate the conditioned count of cotton 500 meters of yarn in Tex. If its oven-dry weight is 10 grams. What is the count at the dry weight?

Solution (8)

D= 10grams

Length = 500 meters = 0.5 kilometer(km)

C.C.W = 10+(10+8.5)/100= 10.85 grams

Tex count = number of grams/ 1 km

Conditioned count =10.85/0.5 = 21.7 tex

Dry weight = 10/0.5 = 20 tex

Q9

Calculate the conditioned count of 20 km cotton yarn, if its oven-dry weight is 800 grams. Also, calculate the denier count.

Solution (9)

D=800 grams

C.C.W = 800+(800×8.5/100)

=868 grams

Tex count= 868/20 = 43.4 tex

Denier count = 43.4×9 = 390.6 denier

Q10

Calculate the M.R, M.C & C.C.W of 100 grams of cotton yarn of its oven dry weight is found to be 94 grams. Also, calculate tex & denier counts at the dry weight and C.C.W. Take 1 hank of yarn.

Solution (10)

O.W = 100 grams

D = 94 grams

W = 100-94 = 6 grams

R = 6/94 x 100 =6.38%

M = 6/94 x 100 = 6%

C.C.W = 94+(94 x 8.5/100)

=102 grams

Count at dry weight = 94/453.6 = 0.207 lbs

English count = 1/0.207 = 4.825s

Tex count = 590.5/4.825 = 122.4 tex

Denier count = 5315/4.825 =1101 denier

Count at C.C.W weight = 102 grams

=102/453.6 = 0.0225 lbs

English count = 1/0.225 = 4.45s

Tex count = 590.5/4.45 = 132.8 tex

Denier count = 5315/4.45 = 1195 denier

Q11

8lbs of cotton when completely dry weight 90 oz. What is the excess of M.R.? Also, calculate the true values of cotton when the price per bale 280 kg at the original weight is $555.

Solution (11)

Total weight = 8 lbs = 8 x 16 = 128 oz

Dry weight = 90 oz

moisture = 128-90 = 38 oz

R = 38/90 x 100 = 42.2%

Excess moisture regain = 42.2-8.5

=33.72%

C.C.W = 90+(90 x8.5/100)= 97.65 oz

Now we calculate the price

280 x 2.2046 lbs = $555

1 lb = 555/280/2.2046 =$0.899

Hence, the true price paid for 8 lbs = 97.65/16 x 0.899

=$5.486

And true price per bale is = 5.486/8 x280 x 2.2046

= $423.305