Aluminium/copper/zinc/lead and its alloys are metals and alloy with these metals which change the world of engineering metallurgy as a whole, here below we will discuss them one by one.

Aluminium

Aluminium is a white metal produced by an electric process from the oxide, which is Prepared from a clay mineral called bauxite. Bauxite is found in large quantities in various parts of the world and the successful extraction of the metal depends upon the supply of large amounts of cheap electricity.

Properties and uses

- Owing to its lightweight aluminium is used largely for aircraft and automobile components where the saving of weight is an advantage.

- The creative density of aluminium is 2.68 as compared to steel with a density of 7.8.

- In its pure state, the metal will be too weak and soft for more purposes but when mixed with small amounts of other alloys it becomes hard and rigid.

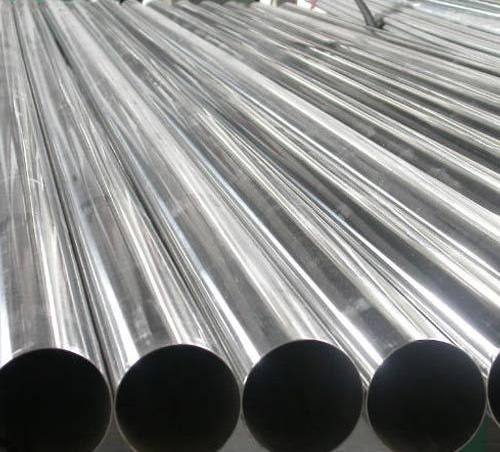

- Aluminium is very ductile and malleable. It can be rolled into a leaf (2/100mm) thick, and drawn into wires (1/10mm) in diameter.

- Also can be given a high finish by polishing it. Aluminium meets easily and may be formed into parts by casting.

- In its natural state, it has tensile strength varying from 90-150 N/mm2, depending upon the amount of mechanical treatment it has received.

- Its good electrical conductivity is an important property and aluminium is used for overhead cables and grid systems.

- The high resistance of aluminium to corrosion makes it a useful metal for cooking pans.

- It owes this resistance due to thin film oxides which cover its surface and protect it.

- Aluminium foils are used for wrapping chocolates and for sealing milk bottles. The powdered metal is used as the base for aluminium paints

Aluminium alloys

It is alloyed with a small number of other metals and then aluminium finds its widest uses.

The addition of small quantities of other metal converts this soft, weak metal into hard. Strong metals with a wide range of applications.

Alloy with Cu and Zn

BS 1490

For the casting of crankcases and for general engineering uses, aluminium is alloyed with a small amount of copper and zinc. The alloy is called BS 1490.

which contain Zn 12.5→ 14.5%, Cu 2.5 → 3%.

It has a minimum tensile strength of 170. N/mm2, and is used for casting.

BS 1476

Far use in bars BS1476 specifies an alloy containing

Cu 2 → 4%, Zn 4 → 8%, and not more the 1% of (Fe, Si). These last two metals are Nea always present in aluminium as an impurity.

For casting which must be tough to withstand shocks and severe stresses Al, Cu Alloy is used containing 12% of Cu.

Important series of casting and forging alloys having high strength has recently been developed for use in aero plant construction, these contain. Cu, Ni, Mg and Zn together with small amounts of other substances. One example of the alloy is as follows:

Zn 5%, Mg 3%, Cu 22%.

Nickel up to 1% and the remainder is an Al to bring this alloy to its maximum strength and hardness. it must be heated (heat treated ) then this has been carried out with an ultimate tensile strength of over 500N/mm2.

Y-Alloy

This alloy also called BS 1470 and BS 1476 and contains 3.5 → 4.5 % of Cu, 1.8→ 2.3% Ni, and 1.8 → 1.7% Mg.

This alloy has the characteristic of maintaining good strength and high temperature. For this reason, it is used for engine pistons and it is also used largely for sheets and strips. After proper heat treatment may be brought to the minimum tensile strength of about 350 N/mm2.

Copper

Copper is easily distinguished from all other metals on account of its red colour. The chief ore of copper is pyrite which contains on average 32% of Cu. Extraction may be done by dry or wet process.

Dry process

It is carried out in a blast furnace and proceeded by various stages that are refinement and followed by various metal refining processes.

Wet process

In the wet process, ores are treated with acids and the metal afterwards precipitated. Electrolytic copper is a pure form obtained by electrolysis from impure lumps of copper.

Properties

The metal is malleable and ductile and becomes of its high electrical conductivity so, it is used extensively for wires and cables and all parts of electrical apparatus which must conduct the current. Also, copper is also a good conductor of heat and highly resistant to corrosion by liquids, for this reason, it is used for boilers,

fireboxes, water heating apparatus, water pipes and vessels in chemical plants. For its high heat conduction, it is used for soldering iron bits.

Copper may be cast, frogged, rolled and drawn into wires. Rolling and drawing harden It. But it may be softened again by heating it to 3200C. The mechanical properties of copper depended on its condition.

Casting may have a tensile strength of 150 →170 N/mm2 which may be increased to 215↔ 230 N/mm2. The strength of hard-drawn copper wire may be as high as 280 ↔340 N/mm2.

Aluminium bronze

Copper alloys with Aluminum give aluminium bronze, and chief alloys contain 6% and 10% of Al, respectively. The alloys have good strength and working properties and 6% aluminium alloy has a fine colour being used for imitation (artificial) jewellery and decorative purposes. The 10% of Al alloy which often Contains 5% Ni and 5% iron is interesting because it can be hardened like high-carbon steel. In its softest condition, the alloy has a maximum strength of about 380 N/mm2 but if it is quenched after heating at the critical temperature, and so then cools down in the water after this material becomes very hard) from 9000C, it is hardened and its strength rises to about twice this amount after hardening.

Copper tin Alloy: (Bronzes)

When alloyed with tin, copper from the rest of the alloys is called bronze which is an important metal in engineering practice.

Gunmetal

Contains 80% of Cu, 10% Tin and 2% Zn, ZN is added to clean the metal and increase its fluidity. The metal is chiefly used for castings which must be strong and resistant to corrosion by water and the atmosphere. Gunmetal is not suitable for cold working but may be frogged at about 6000C.

Phosphorous bronze

When bronze contains phosphorous it is called phosphorous Bronze. The main function of phosphorous is to act as a cleanser to the metal so that good, sound castings can be produced. The common type of phosphorous bronze is Cu 93.7%, Sn 6%, and 0.3% phosphorous. This may be obtained as rods, wires and sheets. When it is severely worked cold as in the drawing of wires, in the rolling of the strip it becomes very hard and springy and is used for springs.

Its tensile strength is then in the range of 500 N/mm2 as compared with 300 N/mm2 in the soft condition. Also, a variety of phosphorous bronze suitable for casting conditions 11% Sn and 0.3% phosphorous alloyed with Cu, is used for bearings which must carry heavy loads, gears, must machines and many other purposes.

Zinc

The chief ores of Zn are ZnS and ZnCO3. Also, in the extraction of metal the ore is first roasted in a furnace to convert the sulphide to oxide and in the case of ZnCO3 to(drive off ) convert it into carbonic acid and water. The one is then mixed with some carbon and put into the same special type of furnace. The heat distilled off the Zn in the form of green white vapour and this condensed to melton Zn, Zinc is a bluish-white metal, which is nearly pure, showing large bright smooth crystals at its fracture.

The metal may be obtained in rolled sheets, the relative density of Zn is about7.1 and its, melting point is 4200C. The malleability and ductility of Zn are Improved by heating it.

100– 1500C but at just over 2000C it becomes so brittle that it may be powdered in its pure state.

The chief use of Zn is for covering steel shields with galvanized iron. The

Covering is done by dipping the sheets into molten metal after they may be dried.

Galvanized wires, nails, and pipes are also made by this process. Also, when rolled into sheets Zn is used for roof covering and for providing a damp-proof non- corrosive lining to containers. Zn casts well and forms the base for various diecasting alloys

Alloys of Zn

Gilding metal

It contains Cu=8%, Zn=15%. This is used for cheap jewellery

English standard brass

It contains 66% Cu, and 34% Zn. Also, It casts well and may be hammered. Little Lead is added to improve the machining.

Lead

Lead is the heaviest of common metals having a relative density of about 11.3 as compared with 7.8 for steel. It has a bluish-grey colour and the surface is dull grey. Also, Lead is very soft and may be easily cut with a knife. It is plastic and malleable being easily forced-cooled into mould shapes and rolled into thin sheets. The chief ore of lead is the “sulfide galena” (PbS)as galena nearly always contains some silvers.

2PbS + 3O2→ 2PbO + 2SO2 PbS + 2PbO→ 3Pb + SO2 (self reduction)

The extraction of lead is generally accompanied by the extraction of silvers as a byproduct.

One of the principal properties of lead is its freedom from any effect due to the action of water and acids and because of this, it is used for water pipes, roof covering and containers in chemical plants. It has a low melting point of 3300C. Also, too large a use of lead is in the electrical and paint industries. Its oxide is used largely as a base for lead paints.

Alloy steel

Plain steels are those containing carbon together with a small amount of manganese and silicon. When casting, special properties are required other elements are added and the steel then becomes known as alloy steel. There are a number of alloy steels used in industry and their applications are wide. We shall discuss only some of them.

High-speed steel

Carbon tool steel after it has been hardened progressively softens as it is again heated up to a lower critical temperature also if this steel is used for cutting tools where the cutting temperature is lightly to be high, softening will occur and the tool will be useless. It has been found that adding Tungsten to steel, is given the property of holding its hardness at a red heat, hence the name high-speed steel.