The structure of wool

In the structure/properties of wool, first, discuss the structure of the fibre.

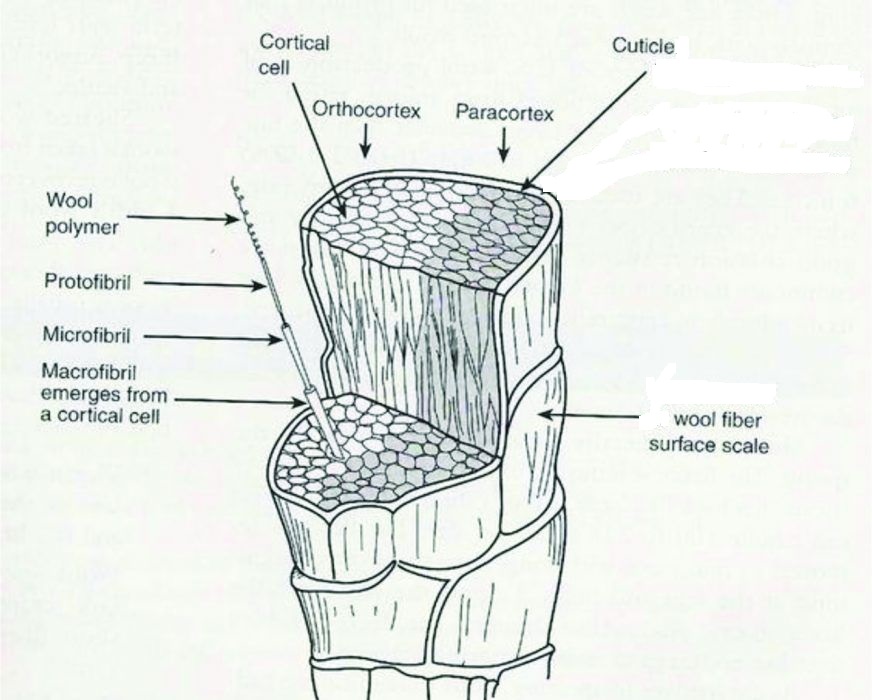

The cross-section of fibre consists of the following three parts.

1-Cuticle

Firstly, it is an outermost layer of wool fibre and is composed of flattering cells called scales. Also, each cell consists of an endocuticle and exocuticle and a cell membrane about 100A0 thick known as an epicuticle. Further, the whole structure constitutes the cuticle and represents 10% weight of the fibre.

2-Cortex

Secondly, the remaining 90% of the wool fibre consists of cellular material known as the cortex. Also, the cortex has two segments, the ortho-cortex and the paracortex. So, the cortical cell of both segments is of comparable size and are enclosed by membranes of at least three distinct layers. Also, each cell is comprised of macro fibrils.

The macro fibrils of the ortho-cortex are small and uniform with well-defined boundaries, whereas the macro fibrils of the par cortex are larger in size and more irregular in shape with undefined boundaries.

Further, the macro fibrils of both types of cells are composed of microfibrils set in a matrix of less ordered material.

The microfibrils are of a uniform diameter of 75A0 but the pattern of their packing from macro fibrils is not the same in the two types of cells. The paracortex has more matrix proteins than the ortho-cortex.

Also, microfibrils consist of protofibrils which are coiled protein chains with their long axis parallel to the main axis of the microfibrils and surrounded by disordered protein. So, protofibrils are about 20A0 in diameter.

3-Medulla

In brief, the central cavity inside the wool fibre is called the medulla. It is generally, in medium and coarse wool fibre. Also, it is not found in fine fibres.

Some of the key dimensions in the structure of wool fibre are

- Diameter of the wool fibre = 200,000A0

- Diameter of the cortical cells =20,000A0

- Diameter of the macro fibrils=2,00A0

- Diameter of the microfibrils=75A0

- Diameter of the protofiberils=20A0

- Diameter of the alpha helical= 11A0

- Diameter of chain (protein chain)

Local wool breeds

All the sheep breeds in Pakistan produce carpet wool because sheep are bred for meat purposes and wool is a secondary product. So, the province-wise distribution of breeds of sheep is given in the table.+

| Provence | Breed | Area |

| Balochistan | Bebrik | Loralai, Sibbi |

| Baluchi | Kalat, Makran, Kharan, Mastung | |

| Harani | Zhob, Loralai, Forts andeman | |

| Punjab | Latti | Mianwali, Attoch |

| Buchi | Bahawalpur, Rahim Yar khan | |

| Kojli | Sargodah | |

| Loh | Jang, Multan, Shawal, Gujranwala, Faisalabad, Sheikhupura, Sialkot | |

| Thalli | Mianwali, Jhang, Muzaffargarh, Jehlum, Multan. | |

| Sindh | Cholistani | Cholistan |

| Dumbi | Dadu, Sahadad kot, Kashmore, Jacob abad | |

| Kooha | Dadu, Jacob abad, Shikarpur, Mirpurkhas, Sukhar | |

| K.P.K. | Michni | Peshawar |

| Kaghani | Hazara, Mardan, Peshawar, | |

| Hashat Nagri | Peshawar, Bannu | |

| Waziri | Waziristan, Banu, Peshawar | |

| Damani | D.G.Khan, D.I khan Perhawar | |

| Balkhi | D. G khan, Peshawar | |

| Swati | Swat, Dier | |

| A.J.K | Kail | Neelam valley |

| Pahari | Mirpur | |

| Chatrali | Chitral |

Properties of wool

In the structure/properties of wool, below discuss the properties of the fibre

Physical properties of wool

The physical properties of wool are

Colour

The colour of wool is due to pigment in the cortical and medullary areas of wool. Basically, the wool has three colours,

- White wool

- Yellow wool

- Coloured wool

Staple length

Significantly, the staple length of wool is an important property. the staple length varies from 1.5” to 15”

- Fine wool 1.5” to 5”

- Medium wool 2.5” to 6”

- Long wool 5” to 15”

Fineness

Basically, the fineness of wool means the cross-section area of wool fibre or its diameter. Also, the fineness of wool varies from 15~40u (micron)

- Fine wool 15~23u

- Medium wool 24~34u

- Courser wool 34~40u or above

Strength

Wool has low breaking strength as compared to other fibres and is one of the weaker fibres. its strength means tensile strength which is 17000~29000 lb/inch2,

Hence, strength and fineness have a direct relationship finest diameter weakest the wool and vice versa.

Tenacity

wool has a tenacity of 1.0~1.7 grams/denier when dry and 0.8~1.6 grams/denier when it is wet.

Kemp

Basically, kemp is chalky white, brittle and undeveloped fibres. Also, the presence of kemp reduces the lustre, strength and quality of wool.

Crimps

Crimp is the curliness or waviness of wool fibre caused during fibre growth. As a matter of fact, if more crimps are present the wool will be better in quality. So, these are the number of weaves per inch,

- Fine wool 30 crimp/inch

- Medium wool 5≥5 crimp/inch

- Long wool 5 and less crimp/inch

Furthermore, the crimp is directly related to the fineness of the wool. A machine is also used to produce synthetic crimps known as crimper.

Medullation

Medullation is the presence of a small hollow portion inside the wool fibre called the medulla which may also be continuous or interrupted. Basically, as modulation increases the strength of wool fibre decreases.

Lustre

The lustre of wool is due to the nature, and transparency of the scale structure. Also, the different types of wool are described in the trade as silver, silk and glass lustre.

Elongation at break

Wool has an elongation at break of 25~35% under standard conditions and 20~50% when wet.

Elastic property

By all means, wool is an unusually resilient fibre. Hence, its high elongation at break causes high elastic recovery. The natural crimp of wool fibre contributes to overall elasticity but their unique property gives the wool respect and is derived from curled, cross-linked structure of the wool molecules themselves. Hence, wool has an elastic recovery of 99 per cent at 2 per cent extension, and 63 per cent at 20 per cent extension.

Specific gravity

Wool is a lightweight fibre also, a specific gravity of 1.32

Warmth property

Wool has a property as an insulator in cold weather. the property is due to crimps in wool, the air is trapped in these crimps and we feel comfortable against chilling.

Effect of moisture

With respect to any other fibre, wool absorbs to more extent and absorbs readily from the atmosphere under ordinary atmospheric conditions. wool will hold 10~18% of its weight of moisture under suitable circumstances. Also, wool absorbs about a third of its weight of water.

Effect of heat

Wool becomes weak and loses its softness when heated at the temperature of boiling water for a long time. Hence, at 1300C it decomposes and turns yellow and chars at 3000C. As a result, it decomposes giving a smell of burnt horn. Burning stops as soon as wool is taken out of flame and a bead is formed at the end of the yarn, this test is used in the identification of wool.

Effect of age

Wool shows little deterioration when stored carefully.

Effect of sunlight

Basically, the keratin wool decomposes under the action of sunlight. Also, this leads to brittleness loss of strength and yellowing of colour with a harsh feeling.

Chemical properties

Following the chemical composition of wool is given in the below table

| Content description | Content percentage |

| Keratin | 33% |

| Dirt | 26% |

| Suint | 28% |

| Fat | 12% |

| Mineral matter | 1% |

Effect of water or steam

Putting water on wool produces heat water molecules that can penetrate between the long molecules of keratin in the wool fibre, hence losing the natural grip of the molecules lying close alongside each other. Also, the molecules are able to move more easily relative to each other and wet wool becomes softer and more plastic.

Steam used over a short period of time has no changing or damaging effect hence, permits the setting of the heat of the crease. Steam and pressure destroy wool rather rapidly, so wool can not be sterilized by boiling but it can be sterilized by means of formaldehyde.

Although water at room temperature has no effect on wool.

Effect of reducing and oxidising agents

Both oxidizing and reducing agents attach the sulphur bonds and must be used judiciously. Since bleaching is carried out by one of these agents so it is much concern at mills. Hydrogen peroxide, an oxidizing agent gives the best permanent whiteness so it is most often used for bleaching wool. So, reducing agents produce an initial whiteness which is not permanent.

According to data the treatment of wool yarn with 1% sodium sulphite solution the additional alkali (0.1 N NaOH) causes much damage to the wool so that even after 30 minutes of treatment, the sulphur content is reduced from 31.6% to 3.04% and after one hour to 2.77%. Hence for bleaching wool with a reducing agent accurate procedure should be followed.

Effect of organic solvents

Chiefly, wool has good resistance to organic solvents

Effect of micro-organisms

Wool has good resistance to mildew and bacteria, though it is not advisable to leave wool for too long in damp conditions.

Effect of salts

Basically, the salt of Ca, and Mg contained in hard water may cause the yellowing of wool on boiling. Also, the salts of heavy metals like Al, Cr, Cu, and Sn interact actively with wool at elevated temperatures and in the presence of an acid.

Uses of Wool

Wool is used in garments, suitings, shall, Sweaters, carpets and also rugs etc.