What is the Knitting?

Kitting is a fabric created by interlocking yarn or thread through the needle. A knitted fabric is elastic, porous, and made much more quickly and easily than woven fabric at a comparatively cheaper cost. Kind of knitted fabrics | List of Knitted Fabrics | Knitted Fabric Names | Type of Knitted Fabrics

Knitting is the construction of interlocking yarn through a needle on a knitting machine. The fabric is knit with two yarns forming loops in each course. Many needles or shafts form yarn loops on knitting machines. The horizontal rows of loops are called courses, and the vertical rows of loops are called wales or ribs.

Characteristic of knitted fabric is light in weight, and comfortable to wear in all seasons. Also, the knitted fabric resists wrinkle tendency, and fit flexibility is a major factor in its large-scale popularity. Knitted fabrics are used in garments and active sports clothing due to their elastic nature for physical activity.

Types of Knitting

Knitting of fabric produced are circular knitting, (also called filling or weft) and warp knitting. Weft or filling knits are horizontal directions constructed from one yarn fed into knitting machine needles.

1- Circular or Weft Knit

The circular or weft knit creates spiral effects in tubular form. These types of knitting machines produce tubular fabric with spiral effects. The horizontal rows of loops are called courses and vertical rows of loops are called wales or ribs. Due to its tubular fabric construction, it is difficult to identify wales and courses.

To get an idea of the weft knitting method, think of hand-knitted sweaters, which weave yarn or threads around themselves. So, when you see the weft knitting pattern of fabric, it has a very obvious V shape. It is also easier to disassemble when there is a hole in the weft knit fabric. However, it provides more stretch to the fabric.

2- Warp Knits

Warp knits are produced using yarn from the warp beam on special warp knitting machines. Unlike weft knits, they use multiple yarns to form loops and adjacent wales.

Warp-knitted fabric is produced by weaving yarn or threads around itself as weft knit, however the pattern is more complicated. Also, the warp-knitted fabric is made by weaving yarn or threads around itself, but the pattern is a bit more complicated. Threads of V shape is not as obvious, however, the patterns are also like stripes. but the V-shaped strips are not very visible. Besides weft knitting it uses multiple threads on beams just imagine a weaving beam. The warp knit production rate is higher and is stronger compared to weft knits.

3- Flat knits

Knitted fabrics are produced using two main methods: weft knitting and warp knitting. Each method is further subdivided into a variety of knit fabric types.

Knitted Fabric Knits

- Weft Knits

- Single Knits

- Lacoste

- Single Jersey

- Double Knits

- Rib Knit

- Purl Knit

- Interlock Knit

- Bird’s Eye

- Cardigans

- Milano Ribs

- Pointelle

- Cable Fabric

- Single Knits

- Specialized Weft Knits

- Fleece

- French Terry

- Intarsia

- Jacquard Jerseys

- Knitted Terry

- Knitted Velour

- Sliver Knit

- Warp Knits

- Tricot

- Raschel

- Milanese knit

Weft knit can be produced by either circular knitting or a flat-bed knitting machine. For filling four basic stitch types are used in circular, weft, or filling knits.

- Rib stitch

- Jersey stitch/plain knit

- Purl stitch

Interlocking stitch (single and double knits)

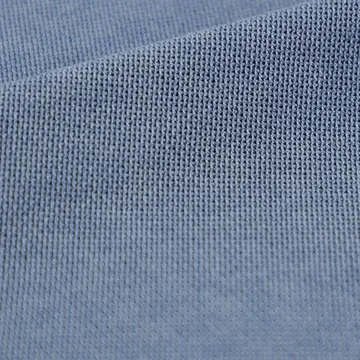

Flat or Jersey Knit Fabric

Jersey Knit or flat knit fabrics is the simplest and economical weft structure. Jersey fabric has vertical flat visible lines on the technical face side of the fabric and horizontal ribs on the technical back of the fabric. A major disadvantage of regular flat knit is its poor dimensional stability, shrinkage, and growth.

Jersey Knit or flat knit fabrics is the simplest and economical weft structure. Jersey fabric has vertical flat visible lines on the technical face side of the fabric and horizontal ribs on the technical back of the fabric. A major disadvantage of regular flat knit is its poor dimensional stability, shrinkage, and growth.

The major advantage is its good stretch recovery about 40% on both wale and course sides. It is fast and inexpensive and can be used to produce varied fancy patterns by using a variety of yarns or double-loop stitches with different lengths to make velour, terry, and plush fabrics production. Jersey fabric is used in casual tops, T-shirts hosiery, etc.

Purl Knit Fabric

Purl Knit Fabrics faces look the same on both sides of the fabric, It has alternative courses of identical and reversible knit stitch and purl stitch loops. Many attractive designs and patterns can be made with the purl stitch. Knitting threads produce Purl Knit as purl stitch and alternate knit in one wale of the fabric. Bulky sweaters and children’s clothing manufacturing are often used. The fabric is more stretchable in length directions remains flat and does not curl. The production speed is generally slow with Purl knits.

Purl Knit Fabrics faces look the same on both sides of the fabric, It has alternative courses of identical and reversible knit stitch and purl stitch loops. Many attractive designs and patterns can be made with the purl stitch. Knitting threads produce Purl Knit as purl stitch and alternate knit in one wale of the fabric. Bulky sweaters and children’s clothing manufacturing are often used. The fabric is more stretchable in length directions remains flat and does not curl. The production speed is generally slow with Purl knits.

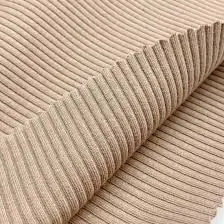

Rib Stitch Knit Fabric

Rib Stitch fabric has columns of wales on both the front and back sides of the fabric. Rib stitch produces fabrics that are good in elasticity. The rib knit fabric is made alternative of purl stitch and knit stitches in one course of fabric. Also, the fabric has alternate wales of purl stitches and knit stitches. It looks identical on both sides and has a reversible pattern fabric. Rib knits are used for the “ribbing” as lower edges of sleeve cuffs, sweaters, and necklines. Rib knit fabric may be made using both flat and circular knitting machines.

Rib Stitch fabric has columns of wales on both the front and back sides of the fabric. Rib stitch produces fabrics that are good in elasticity. The rib knit fabric is made alternative of purl stitch and knit stitches in one course of fabric. Also, the fabric has alternate wales of purl stitches and knit stitches. It looks identical on both sides and has a reversible pattern fabric. Rib knits are used for the “ribbing” as lower edges of sleeve cuffs, sweaters, and necklines. Rib knit fabric may be made using both flat and circular knitting machines.

The most common Rib Knit fabrics are cotton and polyester bases combination with or without Spandex. The other base materials used are linen, wool, rayon, acrylic, etc.

Cardigans

Half cardigans and Full Cardigans are the variants of rib knits. Tuck stitch has specific patterns. Also, these fabric effects produced raised effects that result from a thicker fabric.

Half cardigans and Full Cardigans are the variants of rib knits. Tuck stitch has specific patterns. Also, these fabric effects produced raised effects that result from a thicker fabric.

Full Cardigan

The Full Cardigan is produced in one course of all the knit on front needles and tucked in the back needles as a repeat. It creates ribs or lengthwise ridges and the same series of wales on both sides of the fabric. Excessive tuck loops make the fabric heavy and bulker. A full cardigan is widely used in fashion garments. Cardigan uses materials like wool and Acrylic.

Half Cardigan

The Half Cardigan is produced of one course in two needle beds of all knit and a second course in front needles of all the knits and tuck-in back needles. It creates a tucked rib stitch on the face of the fabric. It. Also, it is a variation of full cardigan stitch. It has less stretch in width. Half cardigan fabric is generally coarsely knitted and used in sweaters and pullovers.

Milano Ribs

Milano Ribs knit is also a variant of Rib, 1- half Milano 2- full Milano. The fabric has a distinctive appearance of horizontal ridges. In terms of functionality, it offers the advantage of restraining expansion as compared to rib fabric. Milano’s rib is a name that has to be assigned due to its origin of being knitted in Milan, Italy.

Milano Ribs knit is also a variant of Rib, 1- half Milano 2- full Milano. The fabric has a distinctive appearance of horizontal ridges. In terms of functionality, it offers the advantage of restraining expansion as compared to rib fabric. Milano’s rib is a name that has to be assigned due to its origin of being knitted in Milan, Italy.

Full Milano

Full Milano is made of a repeat of one course of both needle beds, the second course on the front needles and a third course on the back needles only of all the knit as repeat. Full Milano is used in fine-knitted fabric quality. It gives greater dimensional stability than half Milano rib.

Half Milano

Half Milano is made of one course in both needles and a second in the front needle only of all the knit. One whole needle of rib and the other is jersey. Half Milano rib is mainly used to bind the edges of knit fabric in jersey. Prepared mainly on wider gauge and used to make side edges of blankets, scarves sweaters, etc.