Denim Fabric Guide: Trends, Care, and Style Tips

Denim is one of the world’s most versatile and transcended fabrics its humble beginning as workwear to become a fashion staple in today world’s society. It is known most commonly used for making jeans is cotton twill fabric. The fabric used in denim is most typically is 100% cotton, although other synthetic materials also used. It typically comes in blue, although other shades and distinctive ribbing patterns are also popular. Since denim is popular across international and cultural boundaries, denim jeans become the symbol of the culture of all ages and backgrounds.

| Fabric name | Denim |

| Fabric old name | Serge de Nimes |

| Fabric composition | Dyed cotton yarn is woven in warp-faced twill |

| Fabric breathability | High |

| Moisture-wicking | High |

| Heat retention abilities | Medium |

| Stretch-ability | Low to medium |

| Prone to pilling | No |

| Country where fabric was first produced | France |

| Biggest exporting/producing country | China |

| Recommended washing temperatures | Cold wash |

| Commonly used in | Jeans, jackets, shirts, skirts, suits, hats, belts, shoes, aprons, etc. |

Key Takeaways

- Denim is a versatile fabric that never goes out of style

- Proper care and maintenance are essential to keep denim looking its best

- There are various trends, styles, and colors of denim to choose from

- Expert styling tips can help you incorporate denim into your wardrobe

- Denim fabric is durable and can be used for upholstery projects

Who invented denim: Origin of denim

The history of denim fabric dates back to the 18th century when it was first used as a sturdy laborer’s workwear. The word denim comes from the French “serge de Nimes,” which is particularly a fabric type produced in Nimes, a French town. This cotton weave twill fabric became popular due to its resistance and durability to wear and tear, marking it as ideal for physical labor. Also, its popularity increased around the region and neighboring Italy.

The city of Genoa rapidly became the world’s largest producer of serge de Nimes. Since the French name Genoa is “Genes” the “Jeans” stuck when it gained popularity during the American Gold Rush. Gold miners liked the durability and rigidity of this denim weave fabric and dye color largely available in American West manufacturers such as “Levi Strauss”, a dry goods merchant that used indigo blue dye.

Denim in the 20th century

In the early 20th century denim became a popular symbol in the mainstream fashion industry. It is commonly worn by cowboys, miners, and formers. The mid-20th century marked a turning point for denim, it started gaining popularity among the general population. Hollywood played a significant role in popularizing denim with actors like James Dean and Marlon Brando using jeans and jackets in ionic films like “Rebel Without a Cause” and “The Wild One.”

In the 1960s and 1970s denim became a canvas for self-expression, customizing denim jackets and patch jeans and denim embroidery. So, denim’s influence on the culture continued to grow throughout the decades. In the 1980s and 1990s, denim rose with streetwear and the hip-hop movement. Since now jeans become the fashion statement, Baggy denim looks, and oversized denim jackets popularized by artists like Run-D.M.C and Tupac Shakur.

Denim in the fashion industry today

Denim has now become mainstream in the fashion industry, with designers constantly pushing and innovating boundaries with this ionic fabric. So, from corset tops to denim mini skirts, there is a wide range of denim garments available to suit individual preferences and styles. Also, denim dresses, skirts, and jumpsuits become popular choices for casual occasions. The denim fabric has too many variations to list and mixed with other fabrics weaves and styles.

In recent years, brands have explored sustainable denim, reducing the environmental impact of the fashion industry. Since, organic cotton, recycled denim, and innovative dying techniques are now used in the sustainable denim industry. Traditional Levi 501s remain extraordinarily popular around the world. And niche industry has sprung up that remains around “raw denim” which is part of everyday hipster. Global preference for denim is strong and it is likely be weaves will remain and be produced until cotton is a major textile product.

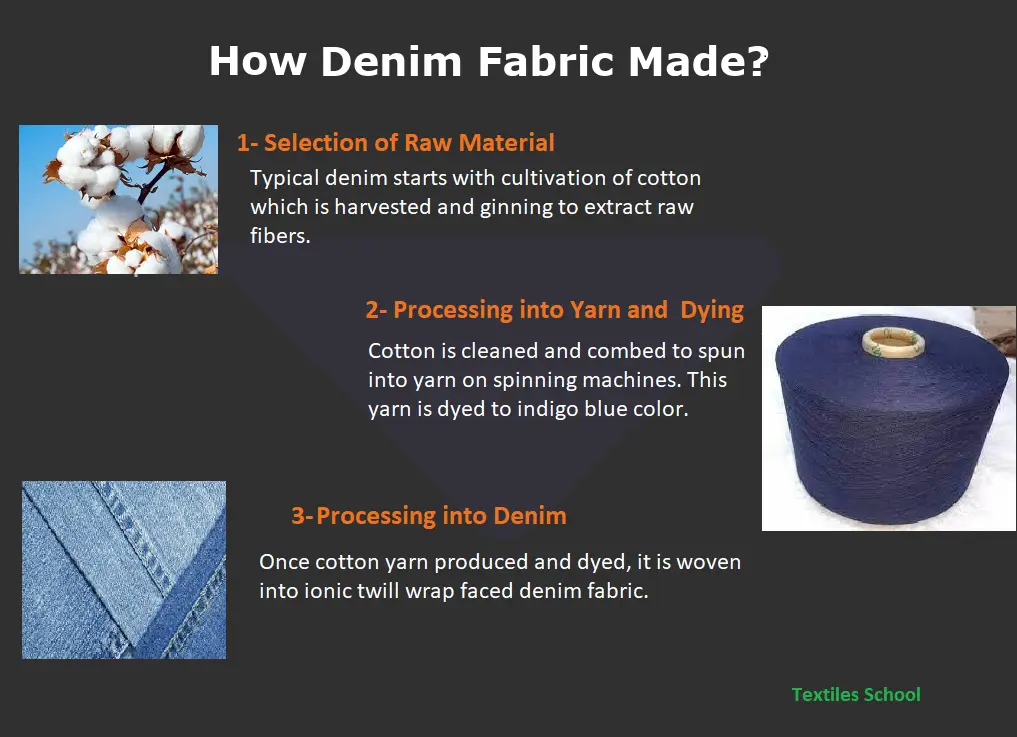

How denim is made: The manufacturing process

The denim manufacturing process includes several stages, each contributing to the quality and appearance. So, there are stages that provide an overview of the typical denim manufacturing process.

Selection of raw material: Cotton cultivation

Typical source of denim fabric material starts with the cultivation of cotton which is harvested and ginning to extract raw fibers. Some other fibers may be included in the percentage as spandex or polyester to add stretch and durability. Long staple cotton is crucial in quality and is preferred for strength and smoothness.

Processing into yarn: Spinning and dying

Cotton fibers are cleaned and combed to remove the impurities and align fiber stand in various machines and processes. This is then spun into yarn on machines called ring-spun or open-end spinning. The yarn is dyed to indigo blue and other desired colors. Also, this dying process involves various machines using different techniques including rope dyeing and slasher dyeing.

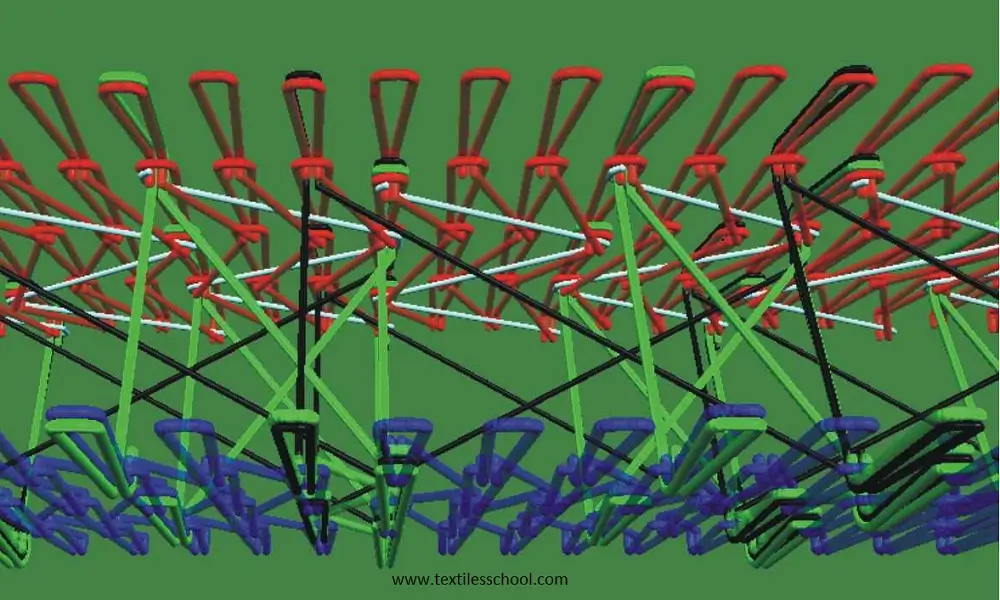

Processing into weaving: Fabric and finishes

As cotton yarn is produced and dyed, it is woven into ionic twill denim fabric. Also, weaving is done on shuttle looms or projectile looms. This weaving process determines the denim’s weight, texture, and pattern. After weaving this fabric undergoes various finishes such as washing, sanforizing (a process to pre-shrink the fabric), dying, and distressing to get the preferred look and feel.

Denim manufacturing is centuries old, with new technologies and techniques continuously developing to improve efficiency and sustainability in the textile industry.

Different uses of denim fabric

Denim fabric comes in various textures, weaves, weights,s, and finishes, each has its unique characteristics some are discussed here,

Apparel

The majority of this fabric is used in denim apparel. Examples of denim apparel items include:

- Jeans

- Denim skirts

- Denim shirts

- Denim blouses

- Denim jackets

- Denim vests

Accessories

Denim is used in accessories like:

- Denim shoes

- Denim belts

- Denim purses

- Denim hats

Homewares

Textile has found a way into the homewares market, the denim become the fashion symbol.

- Denim drapes/curtains

- Denim upholstery

- Denim blankets/duvets

- Denim pillows

- Upholstery Denim Fabric

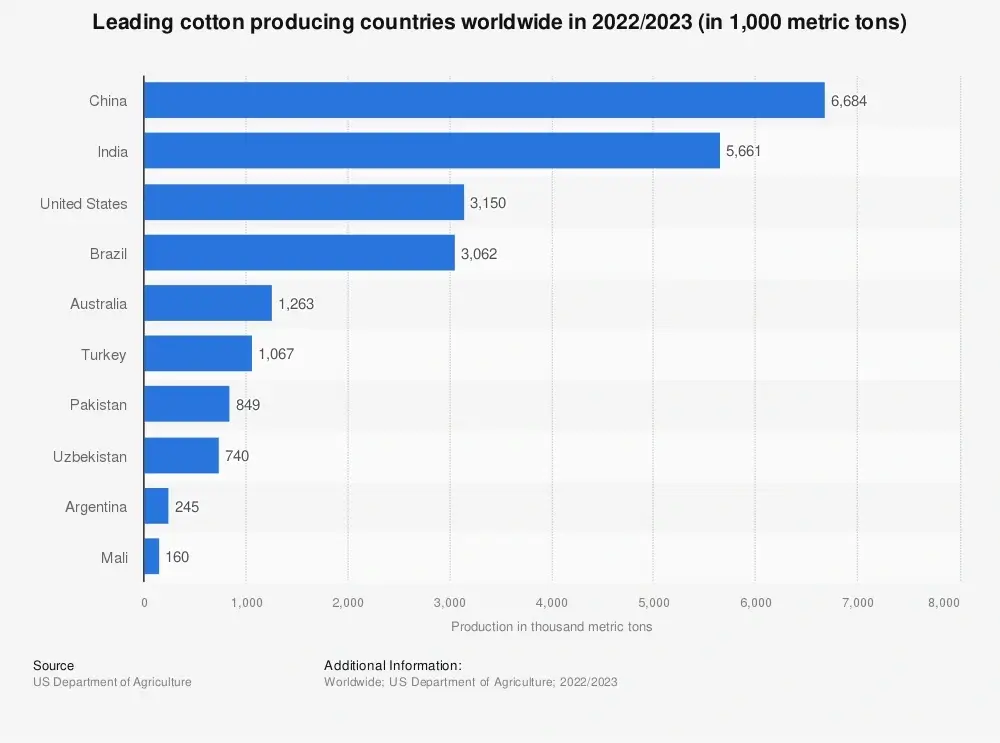

Top 10 denim-producing countries

According to statistics, China is currently the largest producer of cotton in the world. Also, this Asian nation is very closely followed by India with the United States in third place.

These statistics mark something upset in the global market manufacturing order size is 79.2 billion USD, China leading the top major producing denim fabric, Pakistan is the second largest, third-largest by Turkey, followed by India, and the United States.

How much does denim fabric cost

All among the natural fabrics, cotton is even inexpensive and comparable in price to cheap synthetic fibers like Polyester, and Rayan. It sets cotton denim into the middle range of fabric pricing.

However certain types of denim can be expensive. Raw denim, Organic denim for instance can cost dozens of dollars per meter. While cotton products that are produced as sustainable materials can cost more. Supporting goods companies are worried about the increased cost, however, consumers are looking for priced, organic textile products, that provide more profit in the long run.

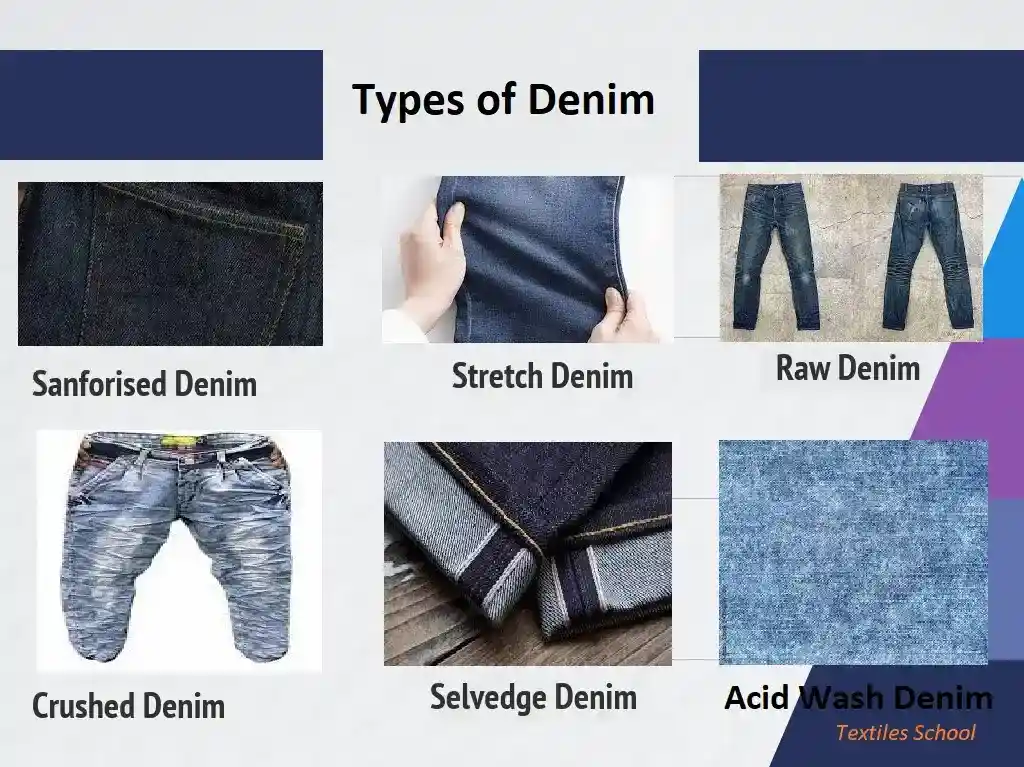

What type of denim fabrics are there

Over the years of development, there have been few forms of denim. Since denim fabric comes in various weights, weaves, and finishes it has its unique characteristics. Here are some most popular options:

1. Raw denim

This type of denim fabric has not been treated or washed, allowing the fabric to develop its unique fading and distressing patterns over time. Moreover, it is favored by denim lovers who appreciate the fabric’s natural aging process.

2. Sanforized denim

Most types of denim fabric have been sanforized, a washing process that results in modern denim. Sanforized is the process designed to reduce the shrinkage of the fabric when washed and exposed to moisture, making it more stable in terms of sizing. Also, sanforized denim is commonly used in the production of jeans, denim jackets, etc.

3. Crushed denim

The weave of denim fabric is similar to velvet. Also, it has a permanent wrinkled appearance making it more appealing for jackets and skirts.

4. Stretch denim fabric

With this type of denim, cotton is mixed with spandex or similar elastomer. The resulting fabric is more stretcher, so it is commonly used in firm-fitting applications like skinny jeans.

5. Selvedge denim

It is prepared on traditional shuttle looms, with tightly woven fabric with clean finished edges. Selvage denim is known for its distinctive and unique edge finish, also known for high-quality construction and durability. And commonly used to make denim jackets, denim shirts, etc.

6. Acid wash denim

Acid wash denim is made by washing raw denim with acid and eating away the dye. Also, this type of denim features an iconic spotty appearance.

7. Poly denim

When mixed with polyester, and other artificial fibers with cotton is termed as “poly denim”. Other synthetic fibers are also mixed like Nylon and Lyocell.

Denim Fabric Trends

Denim fabric is never out of style. This versatile fabric has had countless transformations in history for years, In today’s trends reflect a mix of classic and innovative styles.

- Colored denim fabric: From bright and bold hues to muted tones, colored denim adds a unique outfit. For a chic and edgy look with other patterns wear it as a statement symbol

- Printed denim fabric: It adds texture to your wardrobe and personality. From floral and animal prints to abstract designs, there are endless options. A printed denim jacket with a solid-colored dress has no match.

- Japanese denim fabric has become popular in recent years. Known for its high quality and durability, It is woven by unique technique and dark indigo color. Japanese denim fabric is a raw denim jeans, which become style with wear over time.

- Selvedge denim fabric: Selvedge denim is recognized by its signature colored edge, it is prepared on old old-fashioned shuttle loom. It is typically white with a red or blue stripe. The fabric is popular due to its unique selvedge unique textures.

Denim fabric by the yard

If you are feeling crafty then denim fabric by the yard is the perfect material for sewing projects. Create your denim accessories or make a statement piece, like a denim tote bag.

Sustainable denim: The future of the industry

As sustainability becomes the top priority in the fashion industry. while a variety of ways denim production can impact the system. Like plant crops cotton is potentially a non-polluting substance, however, farmers need to produce high yields with toxic fertilizers and pesticides.

Much more denim in the market is contaminated with high toxins that could harm the wearer’s health, poison the ecosystem, and cause health complications. Moreover, some denim contains a mix of synthetic fiber materials. It is better to know all textile materials other than natural fibers are incredibly dangerous toxins in the environment and can cause multi-generation genetic damage, comparable to atomic bomb explosions and radiation.

“Focus sustainability”

Brands are implementing sustainable practices, such as organic and recycled materials reducing water, and energy consumption, and promoting recycling textile material. A consumer can also contribute to the sustainability of denim by adopting high-quality garments that last for years. Also, embrace second-hand and recycled denim. Nowadays antimicrobial treatment denim has enhanced life span.

Denim fabric certification

Some organizations provide denim fabric certification which is universally accepted.

Supima certification

If you are producing denim which is produced with United States-cultivated organic cotton, you might eligible for Supima cotton certification. Since Supima cotton products are renowned all over the world with strict rules and regulations.

Cradle to Cradle

This organization follows the nature of textile products manufacturing the strict safety standards and sustainability.

FAQ

What is denim fabric?

Denim fabric is a cotton fabric that is known for its twill weave and diagonal ribbing. Also blended with other materials according to requirement. It is durable and resistant to wear and tear. Also, commonly used to make jeans and other clothing items.

What is denim fabric made of?

The fabric used in denim is typically made from 100% cotton. Although some blends with other fibers like polyester and elastane to add stretch and durability is also popular.

How is denim fabric made?

Denim fabric is made through a long continuous manufacturing process that involves cotton fiber production, waste removal, carding, fiber spinning process, dyeing, weaving, and washing process. The cotton fibers or yarn are dyed with indigo to create the characteristic blue color. This is then woven using a twill weave pattern.

Where can I buy denim fabric?

Denim fabric can be purchased easily almost at all fabric stores, online retailers, and specialty denim suppliers. It is available in various weights, colors, and patterns.

What are the different types of denim fabric?

There are several types of denim fabric, including raw denim, sanforized denim, crushed denim, poly denim, acid wash denim, stretch denim, black denim, printed denim, selvedge denim, and lightweight denim. Each type has its unique qualities.

Is denim fabric breathable?

Denim fabric is not known for its breathability. Its breathability is limited than other fabrics due to it is a dense, tightly woven fabric structure that restricts airflow. However, some varieties of denim, such as lightweight denim, may offer slightly better breathability.

Who invented denim fabric?

Denim fabric was originally invented in the late 18th century in France by André Perret and Marc-Marie-Placide Duchamp. It gained popularity in mid 19th century when it was introduced in the United States by “Levi Strauss”

How much does denim fabric cost?

The cost of denim fabric can vary depending on the quality, brand, and type of denim. On average, denim fabric can range from $10 to $30 per yard, with designer denim and specialty fabrics being more expensive.

What is the history of denim fabric?

The history of denim fabric dates back to the 18th century when it was first used as a sturdy laborer’s workwear. The word denim comes from the French “serge de Nimes,” which is particularly a fabric type produced in Nimes, a French town. Also, its popularity increased around the region and neighboring Italy.The city of Genoa rapidly became the world’s largest producer of serge de Nimes. Since the French name Genoa is “Genes” the “Jeans” stuck when it gained popularity during the American Gold Rush.The mid-20th century marked a turning point for denim.