Sewage disposal or effluent disposal

The textile industry uses a huge amount of water and outgoing water consists of many chemicals and impurities. If we do not dispose of this factory wastewater or sewage disposal or effluent disposal it will cause contamination of incoming water and will be injurious to health. The following method is used for the disposal of industrial wastewater.

Dilution

It is the best method of disposing of factory wastewater. “the wastewater is also known as effluent or sewage and the system is called sewage”. For water having fewer impurities, this method is very good. In this method, dispose of the factory the wastewater is either dropped in rivers or canals. The dilution is done so it may not affect the water body. If impurities and chemicals are in excess then it will affect the botanical life hence only temporary pollution is allowed. If water bodies are affected it will be a great loss.

Controlling the waste

The controlling of wastewater before dilution is also done so that excess chemicals and impurities are not allowed to affect marine life. This controlling can be done by

- Recirculation of waste

- Process change

- A change in raw material

- Recovery of matter

- Losser can be checked

It is seen how much this waste is going out. How this waste increases suspended impurities and dissolved solids. The hardness of BOD increases(botanical oxygen demand ), COD (chemical oxygen demand), and how it affects odour colour and PH of the water. If the PH of the water is about to be neutral and other impurities are controlled so as not to affect the water body then it is diluted and disposed off.

Treatment of water

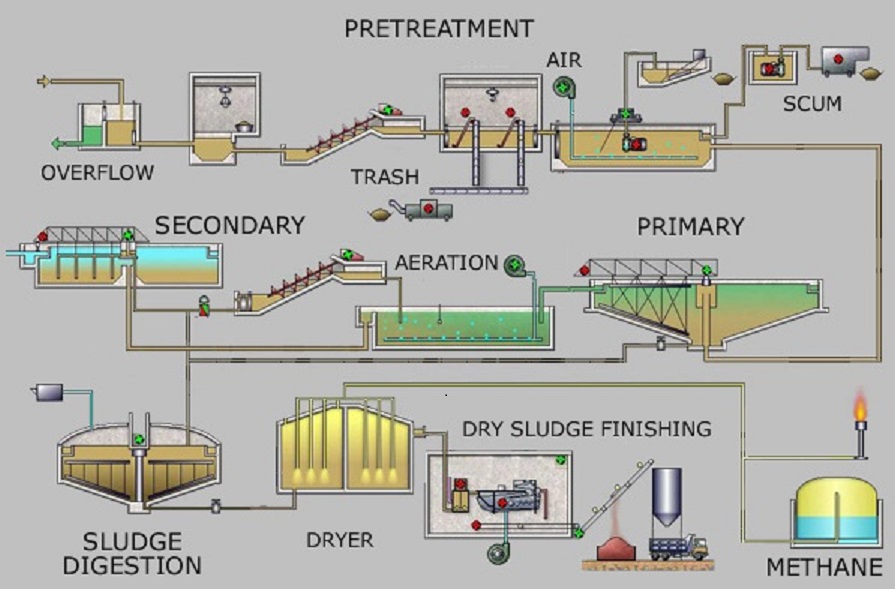

In this method of disposing of factory wastewater, water is treated like municipal treatment. it is economically good because for treatment we check what type of chemicals going out and we can reduce their amount so that fewer chemicals are being wasted. For this, we use municipal water disposal.

In this method, water is first passed through a strainer where the organic impurities are removed. This process is also known as screaming/sedimentation.

The water after this is taken into a reservoir where gases like methane dioxide will be removed. This tank is called an aerator. The water after this goes to settling which has an ejector that moves very slow speed. For coagulation, we put some chemicals Al2(SO4)3 and lime. So, all around these entry tanks there is a jacket and only clear water from the top will go into this jacket and sludges will go into the dryer from the bottom of the settling tank. Also, the sludge is allowed to digest and it can be used as manure and fuel and the clear water having minerals will be used for irrigation.

Dispose of factory wastewater contains

Textile mill waste contains

- Firstly organic suspended and dissolved matter

- Chemicals ( toxics and non-toxic), dyes both alkaline and acidic

- some bleaching agents both oxidising and reducing

- Lime sludge ( as a result of water softening)

- Hardness-causing salts from the boiler below down

- Brine from the generation of zeolites

- Oil minerals and vegetable minerals

- House held sewage

Effect of impurities of water on textile processing

According to the researcher, we require about 7600 litres of water to prepare one pair of jeans.

A textile mill of 25000 ring spindles with a composite unit requires 90000~113000 litres of water in boilers and 450000 ~600000 litres for a whole composite unit. Also to get the best results the water for processing should be free of organic matter, turbidity, and colour and have as low as possible hardness. Moreover, the dissolved T.D.S (solids) should be as low as possible. The effect of these impurities on the finished yarn and cloth is summarised below

Organic matter, turbidity and colour

The turbidity and colour in water are usually due to the presence of organic matter, there will cause detract (non-uniform) brightness of the bleached material purity of shades of colour goods. Organic material which is absorbed by the material is a source of the development of micro-organisms on the cloth which causes found smell and colour spots. It may also weaken or may even cause holes in the material.

Sometimes the colour is due to the peroxides of iron compounds which cause uneven by the hydrogen peroxide bleaching process to their effect on per-oxides. Also, there will be iron spots or rust spots so excessive bleaching will take place causing tendering of cloth.