How a DTG printing can revolutionize your printing process?

In today’s competitive business landscape, finding innovative stand out from the crowd is essential. One such way is the use of Direct-to-Garment (DTG) printing technology. DTG printing gained popularity in recent years due to its high quality of various fabrics and efficient production in print. So, in this article, we explore the advantages of using a DTG printer, how it works, best practices, and troubleshooting. Also, in the end, you will understand the importance why investing in DTG printers to boost your business.

The history of DTG printing

The journey of DTG printing began when researchers found efficient alternatives for screen printing around in 1990s. In the USA in 1996s Matthew Rhome invented the first DTG printer for commercial use. Moreover, these initial experiments opened the way for viable commercial DTG printers in the early 2000s. In 2005 white ink was introduced in the market solving the problem of dark garment fabric. Also, this technology is popular in the textile printing industry. It offered numerous advantages over traditional methods (e.g. screen printing). Such as speedy production, lower costs of setup, and the ability to intricate print designs.

DTG printing market

According to the new report global digital textile printing market will reach 6.65 billion US dollars by 2030. It is estimated an annual growth is 12.1% from 2021 to 2030.

Since, over the years businesses driving demand for DTG printing. Around 9%of the printed T-shirt market with DTG printing technology, with North America in the lead. It has a value of around $2.5 billion with an annual growth rate of 10.8% in the years 2022-2023. Mass customization and environmental benefits are fuelling the growth of an increase in short-run print-on-demand. Additionally, digital printing is an efficient choice for printing garments where there is a high-profit margin and great demand.

If you are looking for digital textile printing ways, which is a subject itself, check out the post on “A comprehensive digital textile printing overview“

You also can see the post on Types of Printing-8 Best Textile Printing Techniques

You also can see the post on Textile printing

Advantages of DTG printing over traditional methods

DTG printing vs screen printing methods has advantages. Here the table below to understand:

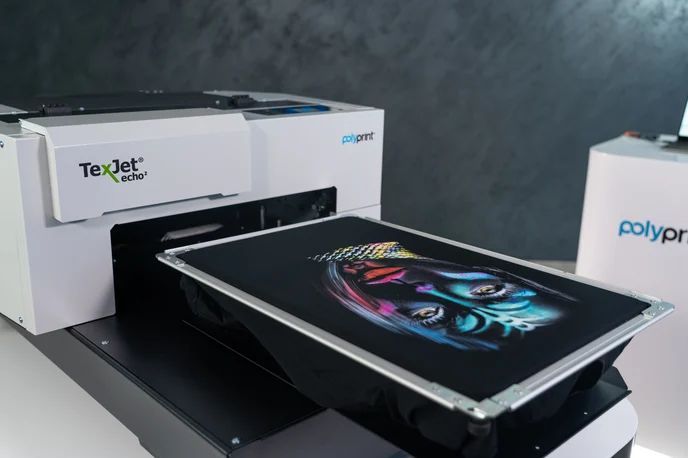

How does a DTG printer work?

To understand the process of a DTG printer one should understand how a DTG printer works.

- DTG printers utilized ink jet technology.

- It directly applies water-based ink onto fabric, creating vibrant and fine detail work.

- The ink is absorbed by the fabric, producing a soft and durable finish.

What is the DTG printing process?

Troubleshooting Tips

Maintainance of your DTG printer is the most crucial step. Checking at regular intervals can avoid unnecessary downtime.

- Clogging the head is a most occurring fault, clean it regularly. A solution designed for cleaning is used for this purpose. Also, place a printer in a clean and dust-free environment.

- If the prints are faded, it is an indication of a low ink level. Also, there may be a clogged printer head. So, check the ink level and perform a clogging cleaning.

- If the printer does not recognize the shirt then check the file format.

- Distorted color then double-check the color setting.

Direct to garment printing recent development printing

Some recent developments in the DTG printing near me industry are as follows:

- Epson recently launched his direct-to-garment printer, Surecolor F3070 with dual-head technology and bulk ink pack system

- Richo recently launched Ri 2000, a next-generation direct-to-garment printer.

- The printhead technology StarFire from Fujifilm Dimatix is being used in Kornit Atlas and also, ROQ NOW models. The StarFire has a printhead built for industrial textile use.

-

RICOH DTG officially launched the Ri 4000 DTG printer at the highly anticipated in October 2023. This innovation revolutionized the textile polyester fabric industry landscape. Moreover, it has a built-in enhancer system, with no need for pretreatment.

DTG printing impact on the textile industry

As a future in DTG printing technology, continuously moving advances. Production of high-standard DTG printers is a game changer for businesses. Since it can produce faster production, intricate design, and an eco-friendly nature. Moreover, the approach of DTG press looks alight with technology. While arising trends and developments to added enhance its potential.